Stop Moulding

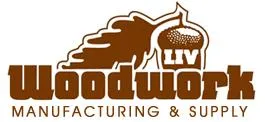

Stop molding is perhaps one of the most under-appreciated pieces of trim in a house, but it can have a major impact on how a door fits, functions, and looks. It is installed along the inside edge of a door frame and provides the boundary against which the door closes, allowing it to fit tightly and reduce drafts, rattling, and gaps.

What is Stop Moulding?

It's a thin piece of trim attached to the jamb on either side of a door frame. It serves the purpose of "stopping" the door in its closing, enabling it to sit flush inside the frame. Without it, doors would swing past the jamb and not close properly.

This simple profile is available in many types of materials, such as wood, MDF, and vinyl. It can be left square-edged for a clean, modern look or feature a rounded contour for more traditional designs. This moulding has a dual role-it enhances both performance and appearance. By sealing gaps and providing a consistent stopping point, it improves privacy, reduces air leakage, and adds polish to the entire door system.

Whether it's an older door update or new installations, this trim adds craftsmanship and precision to the finishing process.

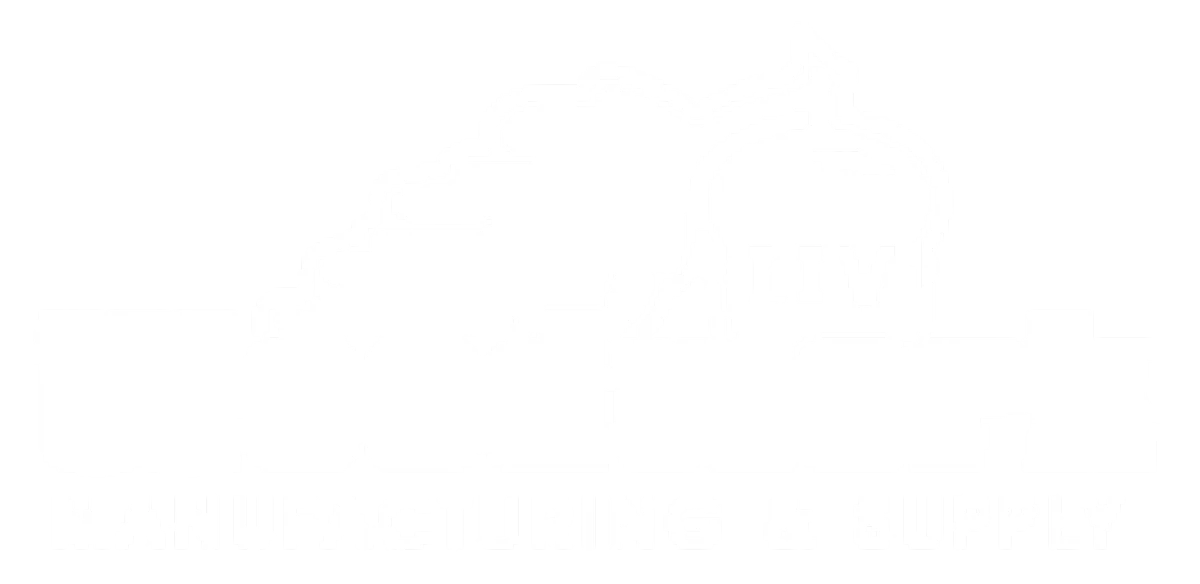

Stop Moulding Profiles

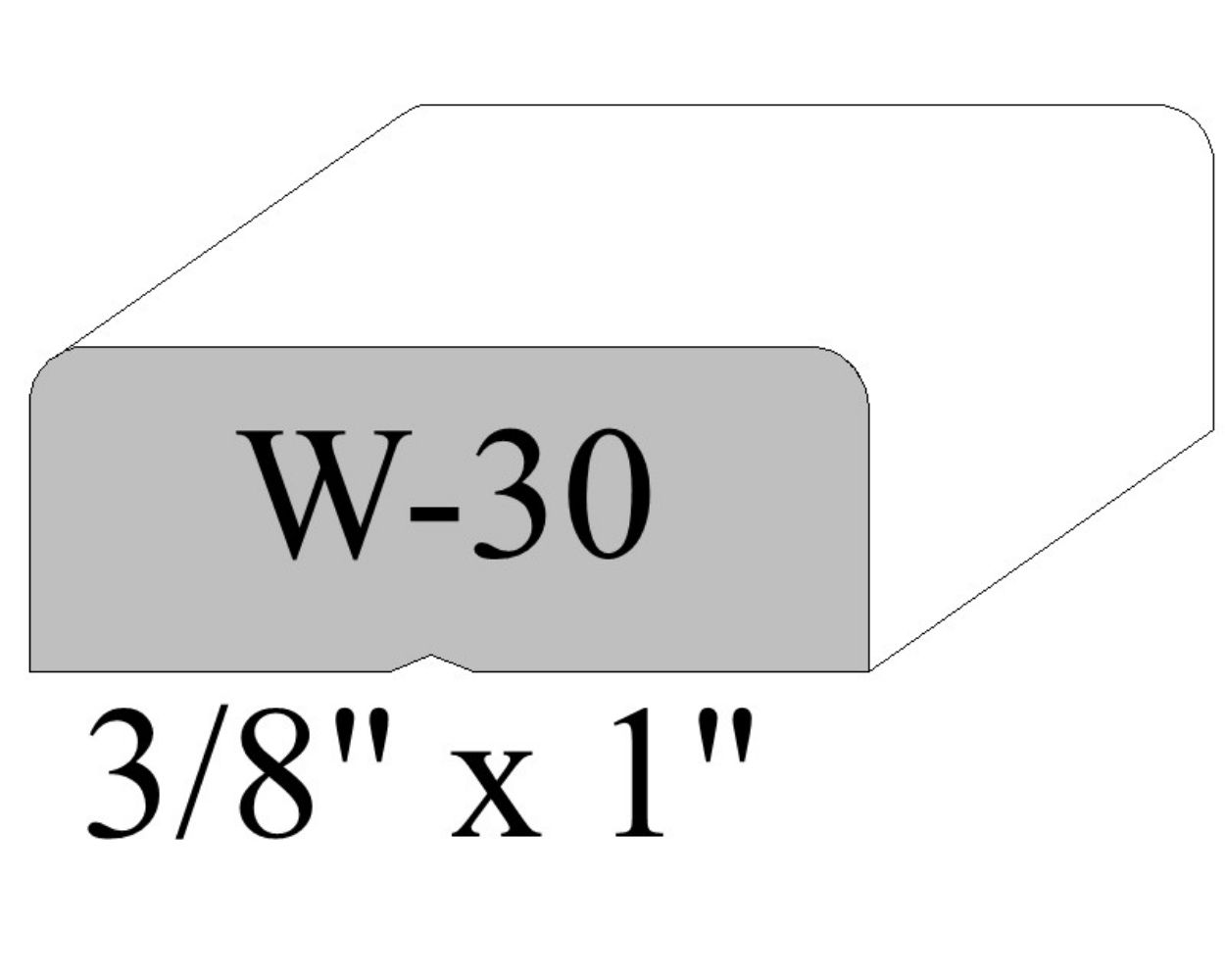

W-30

3/8" x 1"

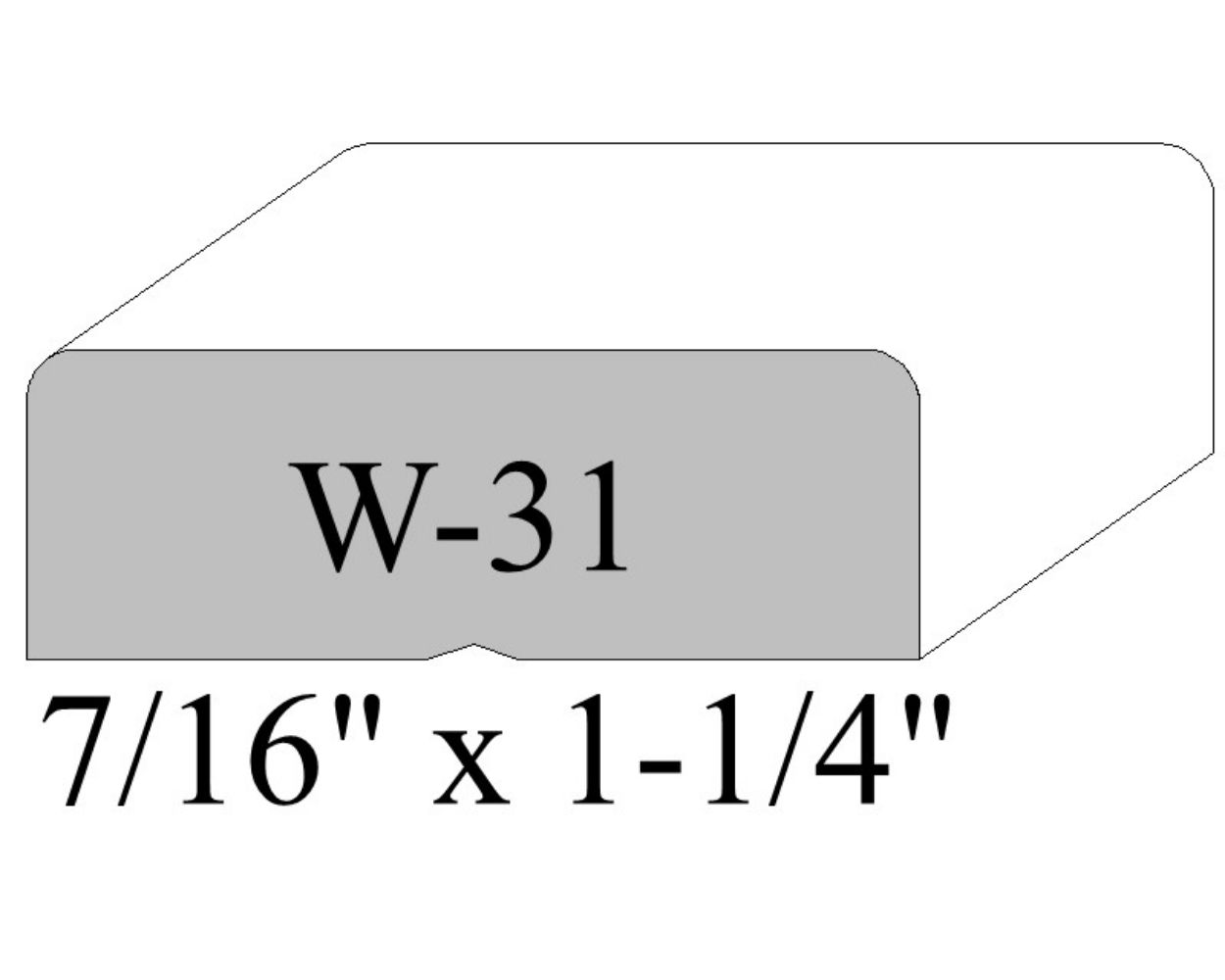

W-31

7/16" x 1-1/4"

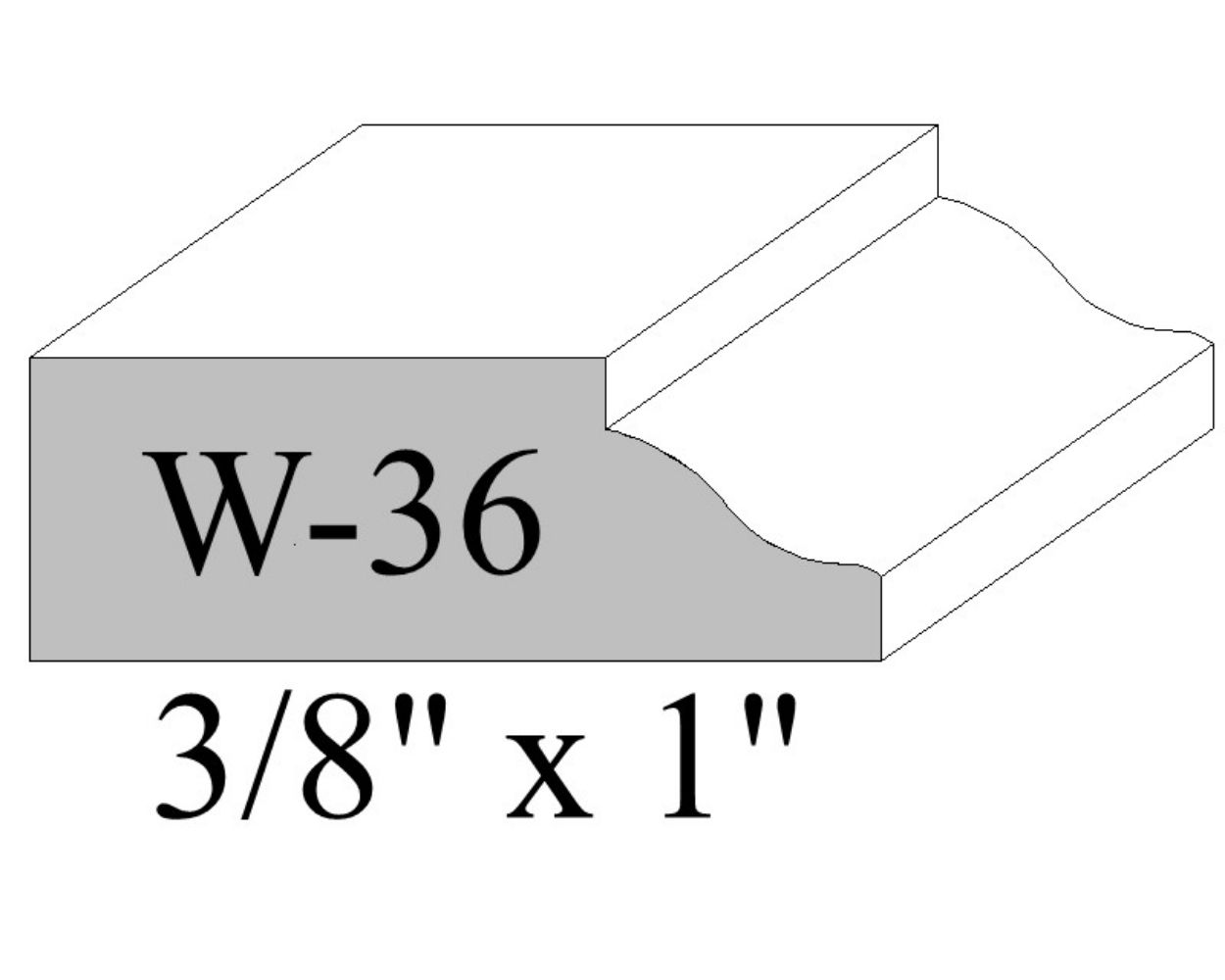

W-36

3/8" x 1"

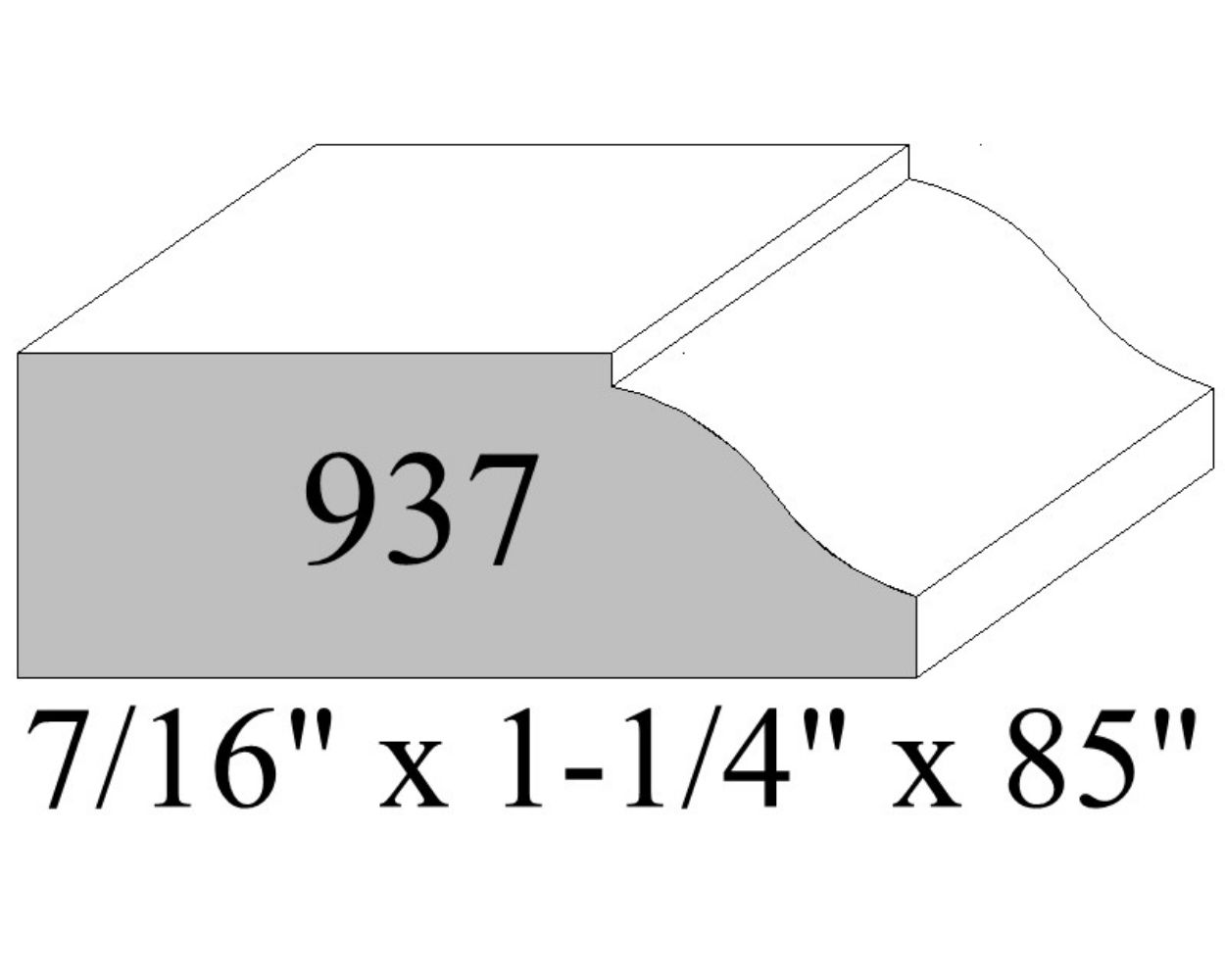

PAC937

7/16" x 1-1/4" x 85"

Stop Moulding Wood Species

Oak

Maple

Poplar

Knotty Alder

Primed

Where to Use Stop Moulding

Interior Door Frames

Provide a secure, quiet closure that prevents doors from rattling or swinging too far.

Exterior Entryways

Increase insulation and weather resistance while enhancing the visual symmetry of the frame.

Closets and Utility Rooms

Add a neat finishing touch to lighter or hollow-core doors for a uniform, professional appearance.

Custom Cabinetry or Built-Ins

Employ scaled-down versions to help doors close neatly against built-in frames or shelving units.

Frequently Asked Questions

What does stop moulding do?

It forms the boundary that stops a door from swinging past the jamb and ensures a proper, secure closure.

Is this moulding necessary for all doors?

Yes, any hinged door that closes into a frame uses stop moulding for function and alignment.

Can I do it myself?

Absolutely, it is lightweight, easy to cut, and installs quickly with small finish nails or adhesive.

Can it be painted or stained?

Yes. Most people paint it to match the jamb and casing, but it can also be stained for contrast.

Does it improve energy efficiency?

It can. Stop moulding, along with weatherstripping, helps in keeping drafts low and providing greater comfort indoors.

Connect with a Moulding Expert

Have questions or interested in working with us? Contact us today to get started.

Types of Moulding Profiles

Choose Your Perfect Moulding Profiles

Used to frame doors and windows, casing moulding provides a clean transition between the wall surface and openings while adding architectural definition.

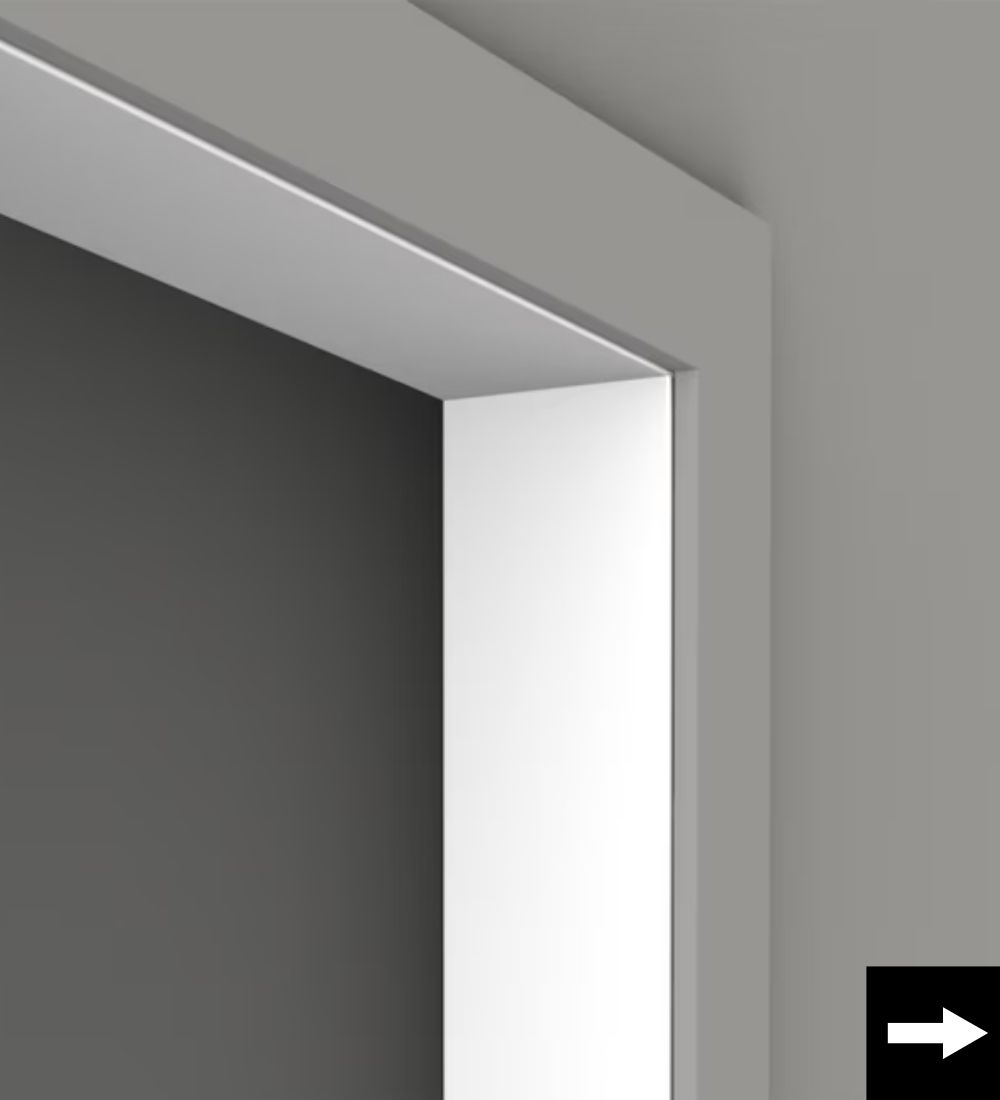

Installed where the wall meets the floor, base moulding protects walls from impact and creates a finished, cohesive look throughout the room.

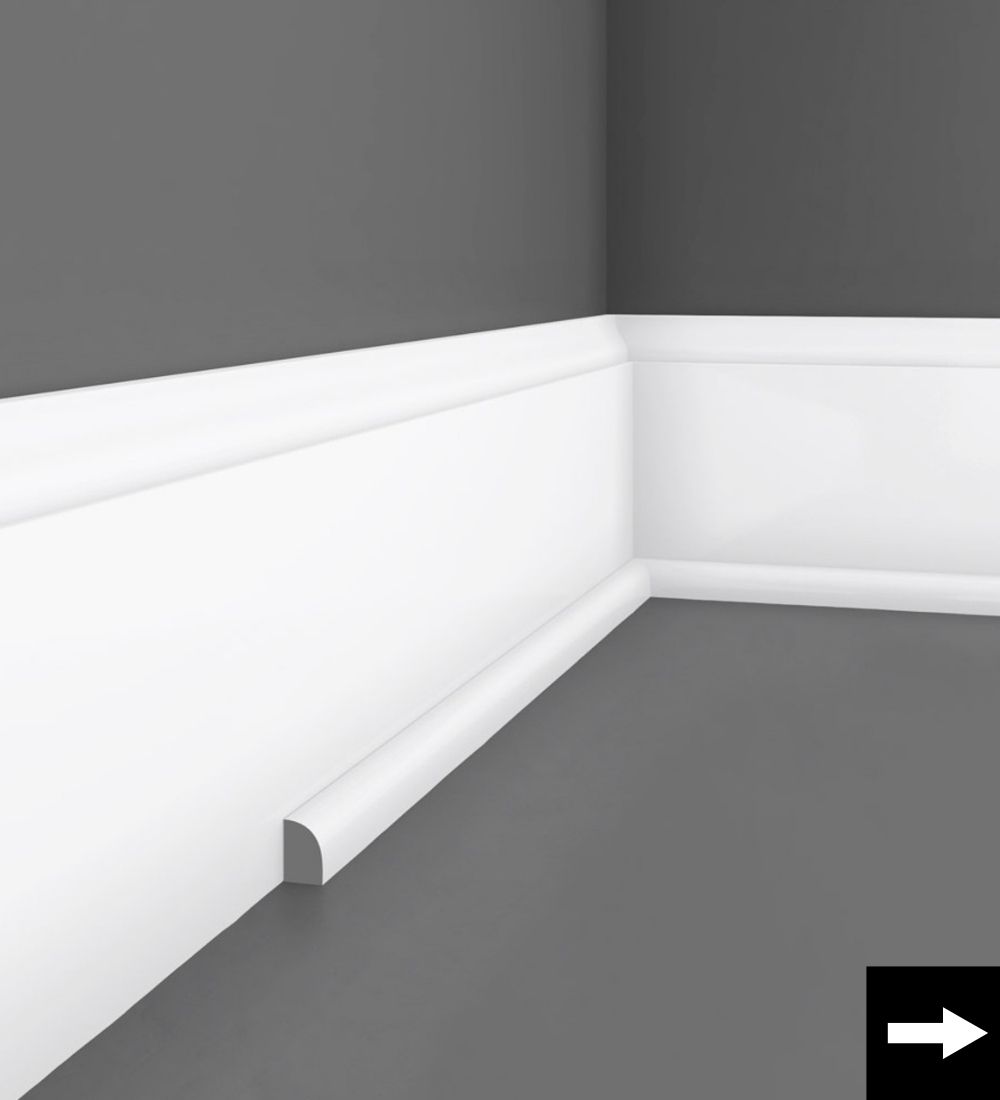

A decorative element installed where walls meet the ceiling, crown moulding adds depth, dimension, and elegance to any interior.

Door jambs form the vertical and horizontal framework that supports a door within its opening, ensuring a precise fit and smooth operation.

Door stops are fitted within the jamb to control the door’s closing position, preventing damage and creating a snug, finished seal.

A small, rounded trim piece installed at the bottom of base moulding to conceal gaps between the floor and wall, often used with hardwood or tile flooring.

Curved and smooth in profile, cove moulding is perfect for soft transitions between surfaces or as a decorative detail in cabinetry and ceilings.

Specially designed to meet fire-resistance requirements, fire-rated casing provides both safety and a clean, consistent appearance around rated door openings.

Panel moulding adds depth and texture to walls or ceilings, ideal for wainscoting, feature walls, or creating custom architectural detailing.

Used to hold glass securely within a door or frame, glass stop moulding ensures a safe, neat, and professional finish.

Additional trim profiles and specialty mouldings designed to meet unique design, installation, or restoration needs — available in a variety of materials and styles.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy