Misc Moulding

When your project calls for unique detail or finishing touches that don't fit neatly into any one category, Misc moulding provides the perfect solution. It's a flexible group of trims designed to enhance both the beauty and functionality of any space, giving you options for creativity beyond the standard profiles.

What is Misc Moulding?

The term miscellaneous moulding refers to the general category of specialty trims that are used for custom accents, transitions, or problem-solving in finish carpentry. These mouldings can also include non-standard profiles, small decorative pieces, or trims designed for unique architectural applications.

They're available in multiple wood species and materials, allowing for a seamless match with other mouldings throughout your project. Whether you're working on a renovation, repair, or a creative build, these trims let you customize every corner, edge, and transition with precision and style.

Misc Moulding Profiles

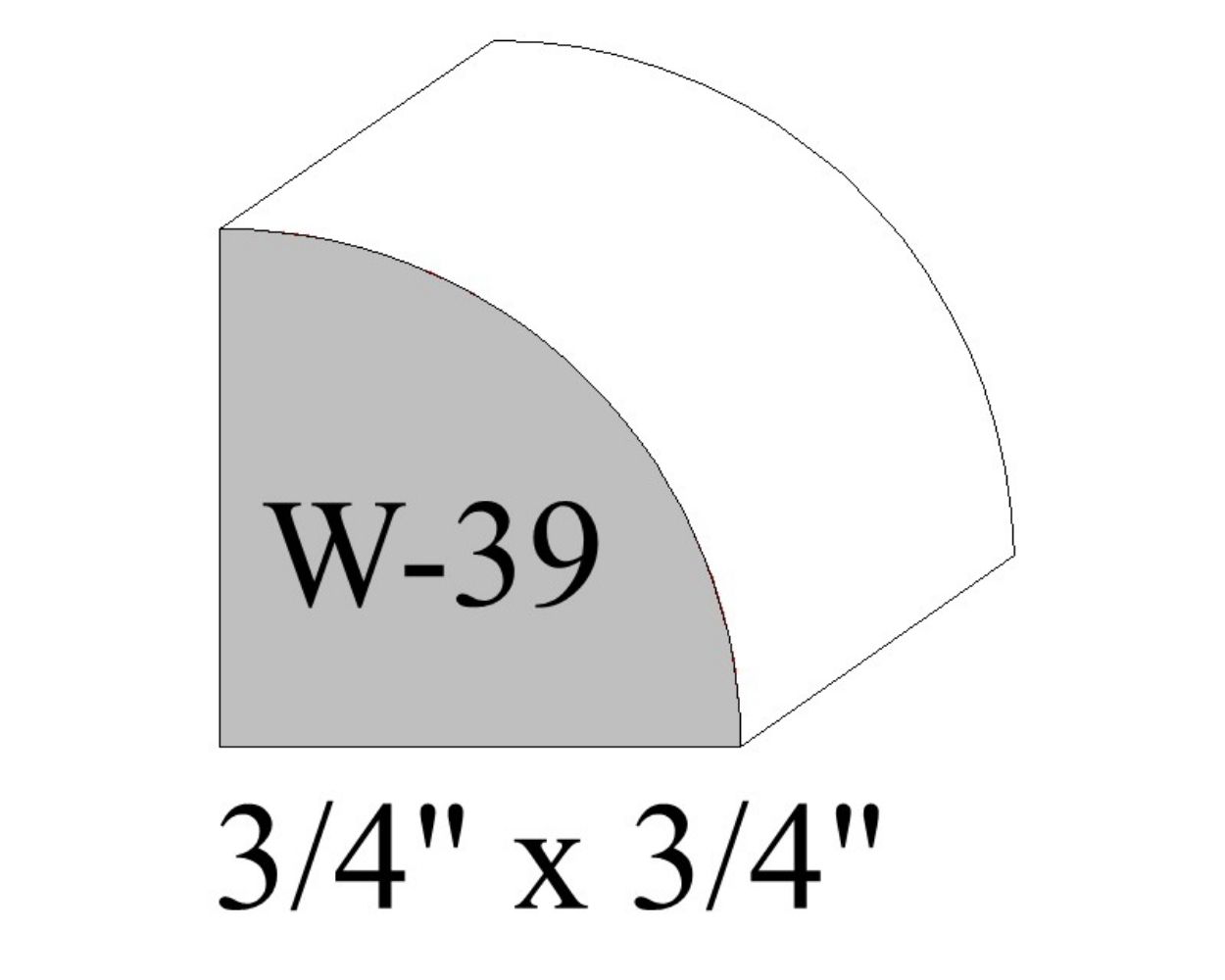

W-39

3/4" x 3/4"

Misc Moulding Wood Species

Oak

Maple

Poplar

Knotty Alder

Primed

Where to Use Misc Moulding

Custom Trim Work

Use to complete edges, corners or built-ins where standard profiles will not fit.

Furniture and Cabinetry

Add detail to shelving, doors, and trim for a tailored look.

Transitions Between Materials

Smooth the join between wood, drywall, or tile for a clean finish.

Restoration or Remodeling Projects

Replicate vintage profiles or patch older woodwork to make repairs blend in.

Frequently Asked Questions

What does "miscellaneous" mean in this case?

It describes moldings that do not come under the standard categories but are necessary for details and finish work.

Can these moldings be painted or stained?

Absolutely-they're made of materials to which paint or stain adheres beautifully.

Are they pre-cut or customizable?

Most are customizable to match your exact project dimensions or design requirements.

When should I use these instead of standard mouldings?

Choose misc moulding when your design calls for flexibility, unique sizing, or one-of-a-kind detailing.

What types of projects use misc moulding?

They’re often used for specialty trim, custom cabinetry, window framing, or any area that needs a tailored finish outside traditional moulding styles.

Do you offer custom profiles or matching options?

Yes, we can help you match existing moulding profiles or create custom designs to ensure consistency throughout your project.

Connect with a Moulding Expert

Have questions or interested in working with us? Contact us today to get started.

Types of Moulding Profiles

Choose Your Perfect Moulding Profiles

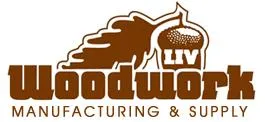

Used to frame doors and windows, casing moulding provides a clean transition between the wall surface and openings while adding architectural definition.

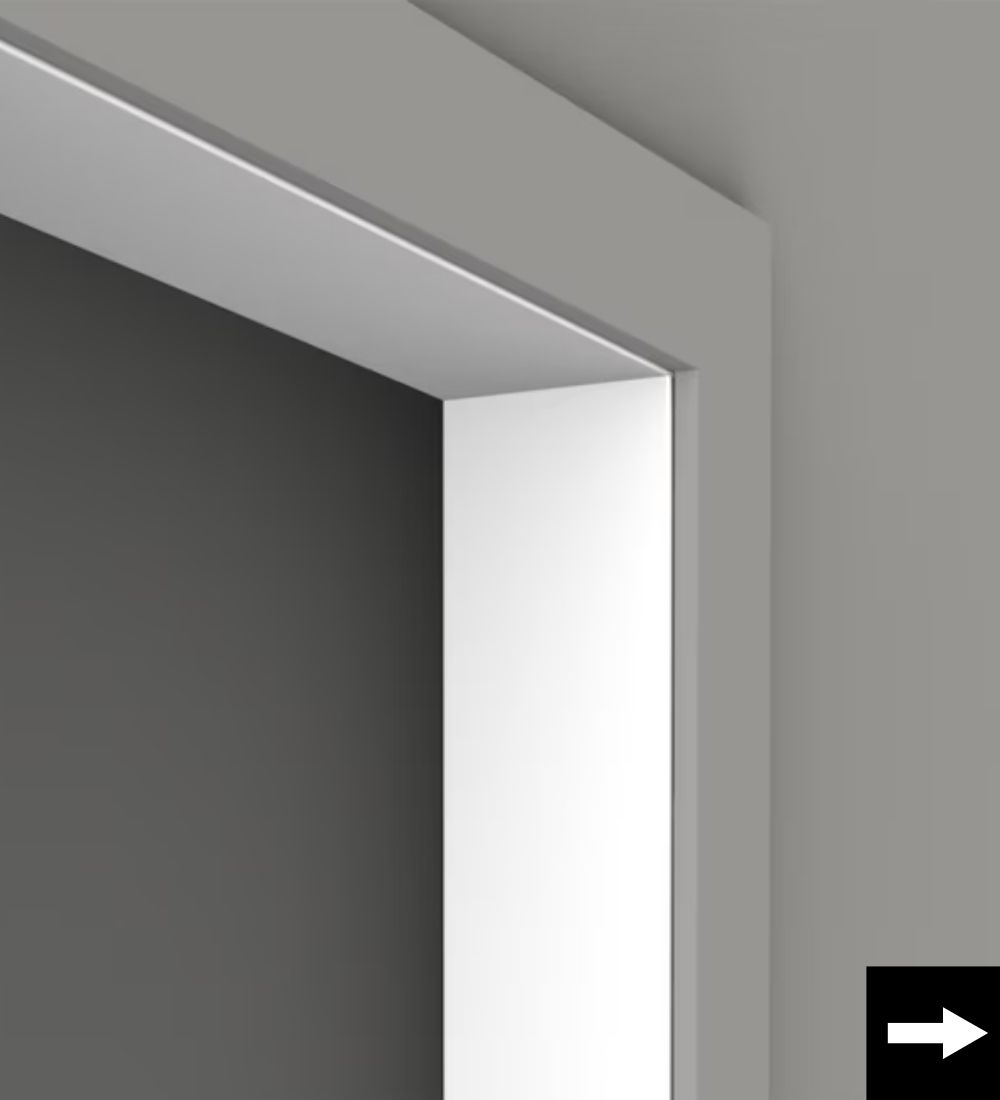

Installed where the wall meets the floor, base moulding protects walls from impact and creates a finished, cohesive look throughout the room.

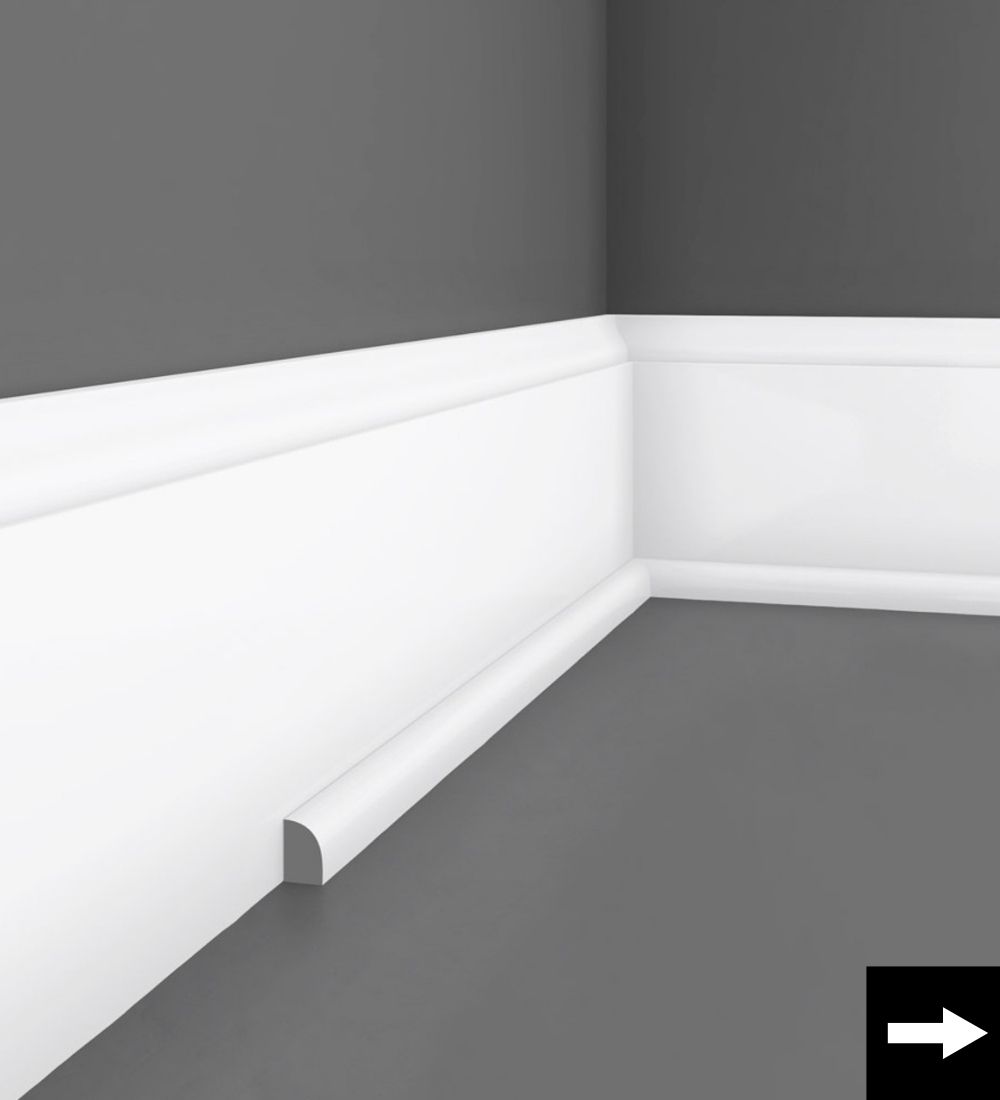

A decorative element installed where walls meet the ceiling, crown moulding adds depth, dimension, and elegance to any interior.

Door jambs form the vertical and horizontal framework that supports a door within its opening, ensuring a precise fit and smooth operation.

Door stops are fitted within the jamb to control the door’s closing position, preventing damage and creating a snug, finished seal.

A small, rounded trim piece installed at the bottom of base moulding to conceal gaps between the floor and wall, often used with hardwood or tile flooring.

Curved and smooth in profile, cove moulding is perfect for soft transitions between surfaces or as a decorative detail in cabinetry and ceilings.

Specially designed to meet fire-resistance requirements, fire-rated casing provides both safety and a clean, consistent appearance around rated door openings.

Panel moulding adds depth and texture to walls or ceilings, ideal for wainscoting, feature walls, or creating custom architectural detailing.

Used to hold glass securely within a door or frame, glass stop moulding ensures a safe, neat, and professional finish.

Additional trim profiles and specialty mouldings designed to meet unique design, installation, or restoration needs — available in a variety of materials and styles.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy