Our History

1925

Founded in 1925

Woodwork Mfg. Co., Inc. was founded in 1925, Incorporated by H. A. Nichols, Frank Nichols, Hubert Steed and W. E. (Bill) Kissick at 4 South Walnut, Hutchinson, KS just across Walnut Street from the Jess E. Liston Tire Company.

The Company motto was “If it can be made of wood, we can do it.”

The Company operated as a planning mill and did custom millwork of all types, including the manufacture of all the wood items in the J.S. Dillon stores, which at the time included all the wall display shelving, island shelving, check stands, water spray produce counters, wood interior decor, etc.

1930

Moving Day

Sometime circa 1930, Woodwork moved to 16 West 4th Street into a new building built by the J.S. Dillon Company. It was built in the style of the Dillon stores of the time in the event they would want to use it as one of their retail outlets at some time. The old Hutchinson streetcar barns were then located just across 4th Street to the South. The Company still did Architectural Millwork and as it grew steadily, started to purchase the materials they needed (lumber, plywood, etc.) in rail car load quantities.

1942

World War II Partnership

At the onset of WW2, it became increasingly difficult to purchase the materials needed for production. This same problem was also proving a difficulty to A. M. Horrall, an entrepreneur from Tulsa, OK who was engaged primarily in the construction of pipelines for the oil industry. While visiting with friends Dwayne & Dwight Wallace, who headed up the Cessna Aircraft Co, of Wichita, he was asked by them if he would be interested in finding an organization to build the bulk of the different wood items that were part of the Cessna aircraft being built at that time. A short time later, Mr. Horrall appeared in the plant of Woodwork Mfg. Co., in Hutchinson and after looking over the operation for several hours, agreed with the two active partners at the time (Frank Nichols and Hubert Steed), to form an aircraft component production company to be named Aircraft Woodwork Mfg. Inc. This was circa 1942.

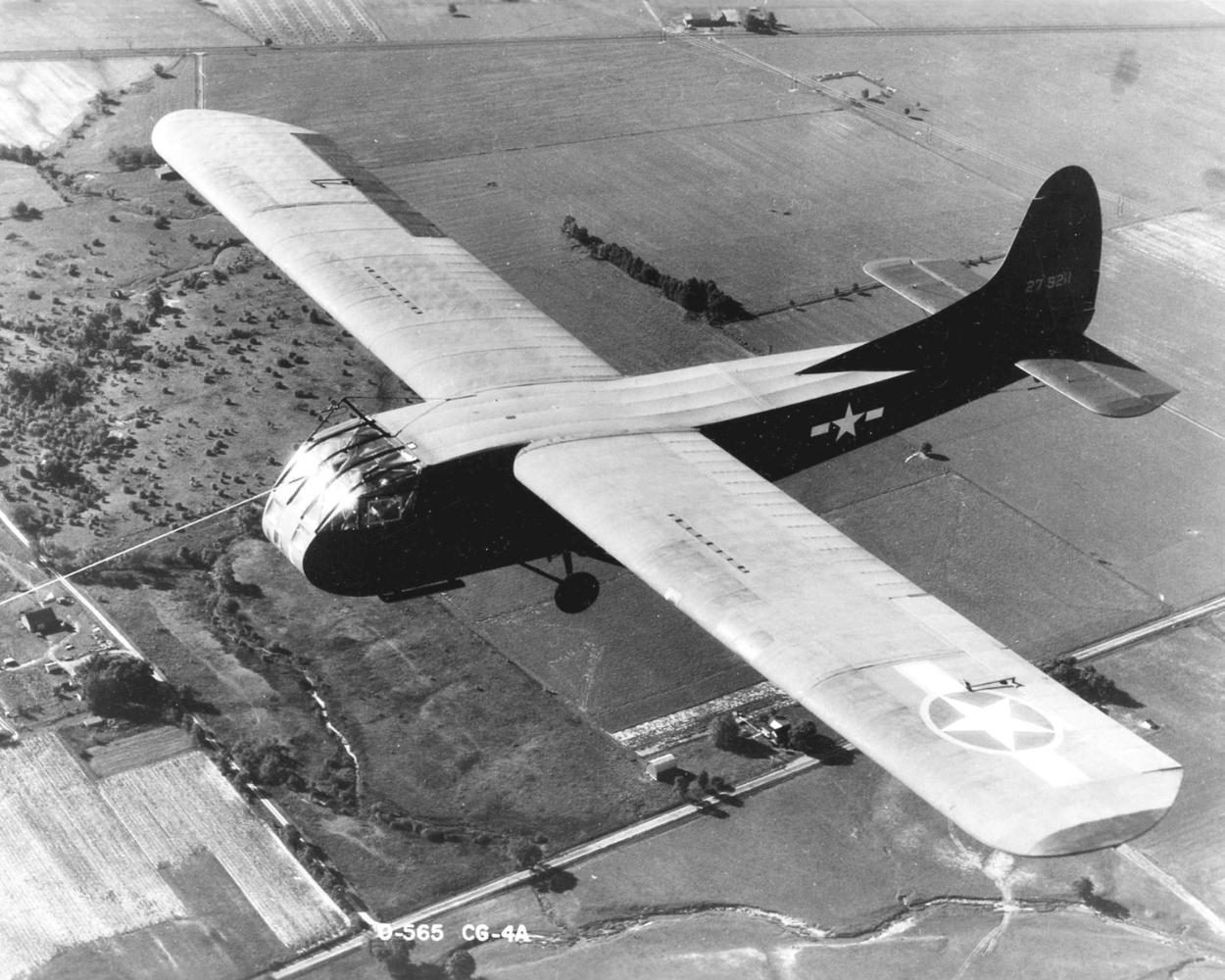

Aircraft Woodwork Mfg. Inc. literally burgeoned from that date. Its first task was to provide several wood components for the CG-4A glider, including the nose section. The glider was a huge aircraft capable of carrying troops, howitzers, smaller trucks, etc.

After production of the CG-4A glider came the production of the Cessna UC-78 “Bobcat” and its Canadian counterpart, the Canadian “Crane.” These were twin engine low wing aircraft used as transitional trainers from single to multi engine ratings and as military personnel transports. Much of the aircraft was made of wood, built around a basic welded tubular framework.

Aircraft Woodwork grew from eight employees to nearly a thousand employees in a short time and working up to three shifts a day. It also grew from occupying two buildings on West 4 th to 11 buildings located between 4th & 7th Streets North & South, and between Main & Washington Streets East & West.

The main offices were in the Wolcott Building. The huge pool of people available for employment came as a great part from women who had never worked outside the home, and men whose normal occupation had been disrupted by the war effort.

As the War wound down the Bobcat and Crane, being primarily training aircraft as opposed to fighting and cargo aircraft, were discontinued fairly early.

1947

Returning to Normal Operations

After the war. Aircraft Woodwork Mfg., Inc. again became Woodwork Mfg., Co. and slowly resumed its normal operations. H. A. Nicols and W. E. (Bill) Kissick retired from the firm and Hubert Steed passed away in 1947, leaving Frank Nichols and Charlie Steed as partners in the business. During the following years, the firm grew steadily, carrying on its manufacturing operations, expanding them to include store and bank fixtures, and architectural millwork for new schools, hospitals, churches, etc. A large materials supply operation was added, and the name changed to Woodwork Manufacturing & Supply. This operation occupied 9 buildings in the West 4th vicinity, warehousing and selling all types of hardwood lumber, plywood, windows, doors, mouldings, and trim. Still later a large builder’s contract hardware section was added, allowing the firm to furnish all the hardware on all types of new construction along with the millwork requirements. From Hutchinson to the Western part of the State was the territory primarily serviced by these operations.

1973

New Owner, Dick Currie

On August 1, 1973, Frank Nichols and Charlie Steed decided they would like to retire, and the business was sold to Dick Currie who owned and operated Architectural Millwork, Inc. Both companies continued to carry on their roles and Woodwork Mfg. & Supply became known as a Division of Architectural Millwork.

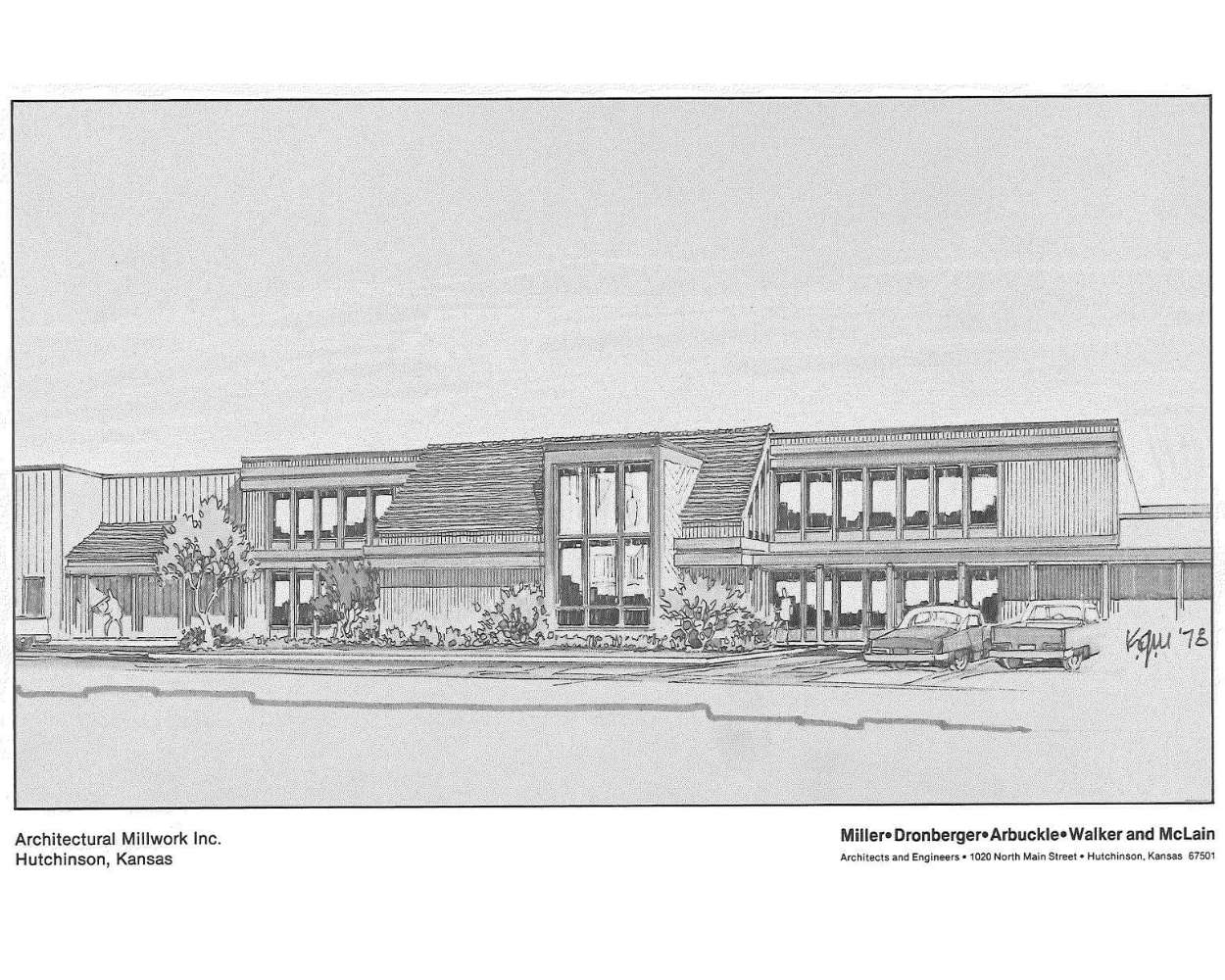

In 1978 Dick Currie decided to consolidate his two Companies to one location and broke ground on their new 117,000 SF facility located at 401 S. Adams. The General Contractor was Ewing Construction. Construction was completed in 1979. This was a new State of the Art facility that combined Warehouse space, Manufacturing Space and Corporate offices all under one roof at a cost of $1.6 million for the plant and equipment. (This translates to $6.8 million in 2025 value). The project was financed through an Industrial Revenue Bond.

Woodwork Mfg. & Supply primarily handled the Residential market for windows, pre-hung doors, trim, stair parts and hardware and its primary role became distributor of building products. In 1981 Woodwork opened a second showroom and office in Tulsa, Oklahoma to expand its market and used an outside sales force to call on Residential Contractors. Woodwork later closed its Tulsa office in the spring of 1990 as the oil market and economy crashed.

1983

Jay Schrock Buys Woodwork

On February 1, 1983, Dick Currie sold off the Division of Woodwork Mfg. & Supply to Jay Schrock who moved the Company to the old Merchant Warehouse which was originally used as a distribution center for local Grocery stores, (Dillons & Safeway), and later was used by Kamen Supply who sold plumbing fixtures. This Warehouse was located at 320 S. Washington, just one block East of Architectural Millwork.

At the time of the change in ownership Woodwork had a non- compete with Architectural Millwork and had agreed to continue buying all its mouldings from AMI for a period of 7 years but could continue to pre-hang its own doors and sell to the Residential Market. Woodwork used the main floor for office space and a small showroom, and the rest of the 1 st level was Warehouse space that was filled with racks of doors and trim. A door machine and pre-hanging department was also on the 1 st level. You could get to the 2 nd level by using a freight elevator or stairs and that is where the window inventory was kept and where the window units were mulled together before shipping out to a jobsite.

Jay Schrock had started working for Woodwork on March 2, 1960, as a truck driver making deliveries. At that time Woodwork was located on 16 West 4 th Street. Jay Schrock had worked in all aspects of the business at Woodwork and by the time Dick Currie bought the company in 1973, he had named Jay Schrock the General Manager of the company, so it was a natural fit when Dick Curie offered to sell the Woodwork Division to Jay.

1989

Expanded Operations

In September of 1989, Woodwork Mfg. & Supply had purchased the buildings at 309 & 311 S. Washington and got back into the business of manufacturing custom hardwood mouldings and keeping a large inventory of hardwood lumber. Woodwork had Salesman that lived in Hays, Pratt, Hutchinson, Wichita and Manhattan. The sales team called on General Contractors throughout the State and parts of Oklahoma.

Woodwork continued to expand its product line by adding Hollow Metal doors and frames in 1996 and put this operation and other inventory in buildings on South Main. As the company grew it once again became spread out in several different buildings and was looking for ways to increase efficiencies. Jay Schrock and his son Jeff Schrock (who joined the company in 1988), had started looking for a new home which would allow consolidation of all its operations. On October 18, 1999, Woodwork was able to purchase the building it had moved from just 16 years earlier at 401 S. Adams. Woodwork was now back in the 117,000 SF facility and was able to consolidate all its operations under one roof.

2015

A Family Legacy Continues

In 2015 Jay Schrock made the pivotal decision to transition leadership of Woodwork Mfg. & Supply, to the next generation. His two children Jeff Schrock and Teresa Schrock Wagner took on the mantle of responsibility. Jeff rejoined the company in a remote capacity while maintaining his role as part-owner of Gaithersburg Cabinetry in Virginia. Teresa, who had been with the company since April 1997, continued her dedicated service in a leadership role.

On March 31, 2016, after an extraordinary 56-year commitment to Woodwork Mfg. & Supply, Jay Schrock retired as President. Though stepping down from daily operations, he remains an active member of the Board of Directors where his guidance and vision continue to shape the company’s future. Jay’s leadership stands as a cornerstone of the Woodwork Legacy, building on the values instilled by those that came before him.

Jay instilled in his children the principles of hard work, integrity, and a commitment to excellence-values that remain central to the company’s mission. Over the years, Teresa and Jeff have witnessed the transformative impact of these principles on Woodwork’s success, fueled by passion, perseverance, and a dedication to producing quality products.

Reflecting on the company’s legacy, Jay emphasizes, “One of my guiding principles has always been ensuring that Woodwork Manufacturing delivers the highest-quality products paired with the friendliest service.”

2026

Present Day

Since Teresa Schrock Wagner and Jeff Schrock assumed leadership of Woodwork Mfg. & Supply in 2016, they have focused on strategic growth and modernization. Over the past nine years, they have invested nearly $1 million in upgrading equipment and vehicles to enhance operational efficiency and product quality. Major acquisitions include a new CNC Door Machine, Moulder, Forklift, 24’ Box Truck, Planer and Gang Rip Saw, Priming Machine and a Tractor with a 48-Trailer. Committed to continuous improvement, they aim to replace or update at least one piece of equipment annually or as needs arise.

For over a century Woodwork Mfg. & Supply has been a cornerstone of the Hutchinson Business Community. The company takes pride in its legacy of dedicated employees who have contributed to producing quality wood products for homes and buildings across Kansas and as far away as the Hawaiian Islands.

As Woodwork Mfg. & Supply embarks on its second century of operations, the Schrock family remains steadfast in upholding the principles established by the company’s founders, Mr. Nichols and Mr. Steed.

Today Woodwork Mfg. & Supply specializes in premium hardwood mouldings, millwork, doors, windows and hardware. The founders’ original mission “If it can be made of wood, we can do it,” - continues to guide the company’s dedication to craftsmanship and innovation.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy