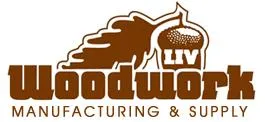

Fire Casing Moulding

Fire casing moulding is the perfect choice for each doorway in your home or business that requires both beauty and protection. It is much more than a decorative trim, as it gives a finished and professional appearance while playing its important part in fire safety and compliance.

What is Fire Casing Moulding?

Fire casing moulding is the special trim placed around door openings to cover the gaps and add a finished touch. The difference it makes from other moldings consists of the materials it is made from, usually fire-resistant or treated to help in controlling the spread of flames and smoke in case of fire.

These mouldings are designed for both form and function. They come in many profiles, wood types, and finishes to match any interior design. Whether you're outfitting a modern commercial space or renovating a traditional home, this trim helps you maintain your aesthetic while enhancing safety and code compliance.

Fire Casing Moulding Profiles

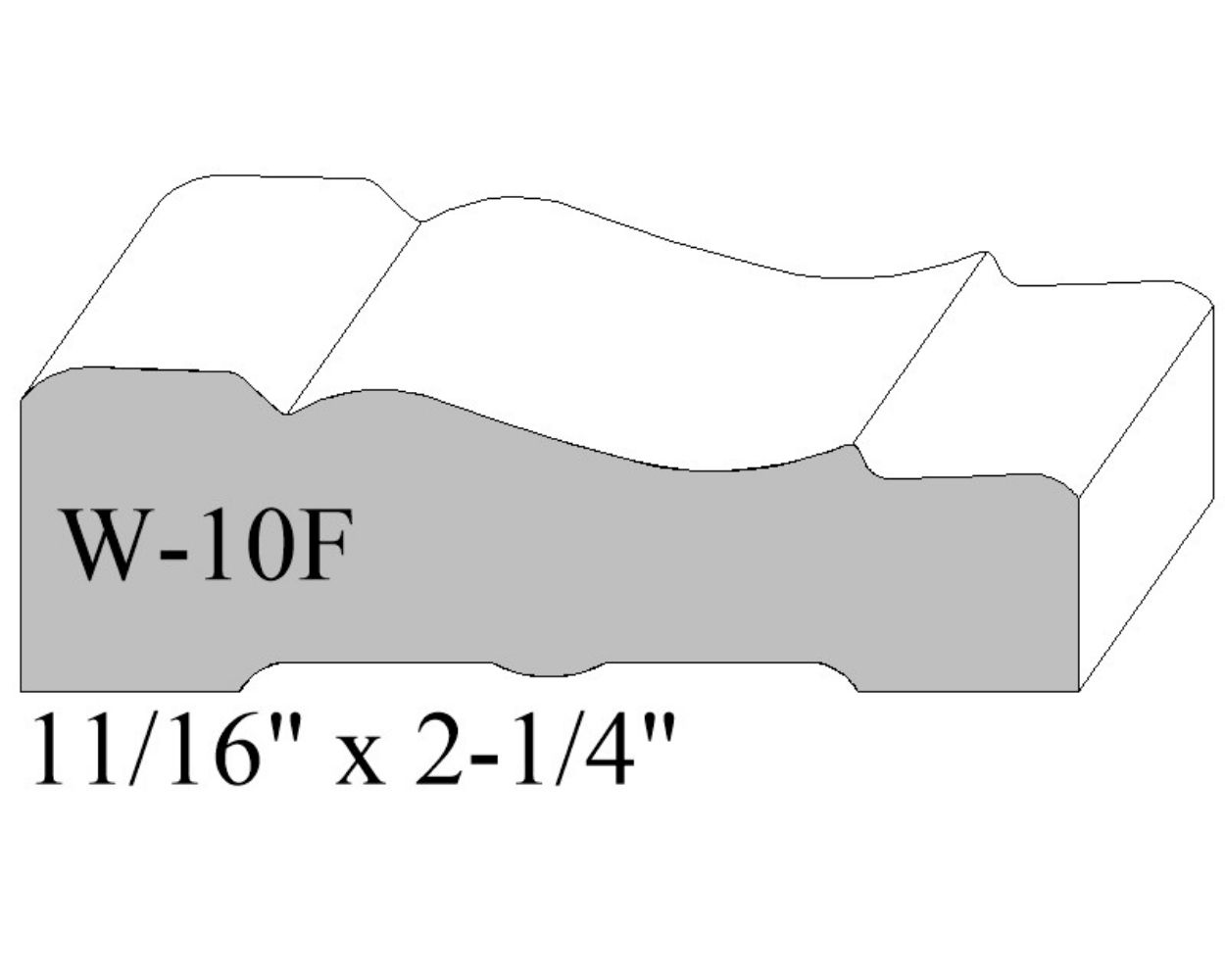

W-10F

11/16" x 2-1/4"

Fire Casing Moulding Wood Species

Oak

Maple

Poplar

Knotty Alder

Primed

Where to Use Fire Casing Moulding

Interior Door Frames

Provide a clean, professional finish that supports fire-rated door systems and conceals installation gaps.

Commercial Entrances

Enhancing the visual balance without sacrificing conformity to fire safety standards.

Hallways and Stairwells

Add a protective edge to busy areas where safety and style are equally important.

Apartments and Multi-Unit Housing

Ensure fire-rated framing for added safety and appeal is consistently maintained with multiple entries.

Frequently Asked Questions

Is this molding only used on commercial buildings?

No, it's ideal for both commercial and residential fire-rated doors.

Can it be painted or stained?

Yes, as long as your chosen finish doesn't affect its fire-resistant surface.

Does it need special installation?

It's best installed by professionals who have experience with fire-rated systems.

What sizes are available?

You can choose from standard widths or request custom sizing for unique openings.

What materials are used for fire casing moulding?

Fire casing moulding is typically crafted from hardwood or specially treated materials designed to resist heat and flame spread while maintaining a clean, finished look.

How does fire casing moulding enhance safety?

It helps seal and protect the edges of fire-rated doors, preventing heat and smoke from spreading through gaps during a fire—an essential part of maintaining a door’s fire rating.

Connect with a Moulding Expert

Have questions or interested in working with us? Contact us today to get started.

Types of Moulding Profiles

Choose Your Perfect Moulding Profiles

Used to frame doors and windows, casing moulding provides a clean transition between the wall surface and openings while adding architectural definition.

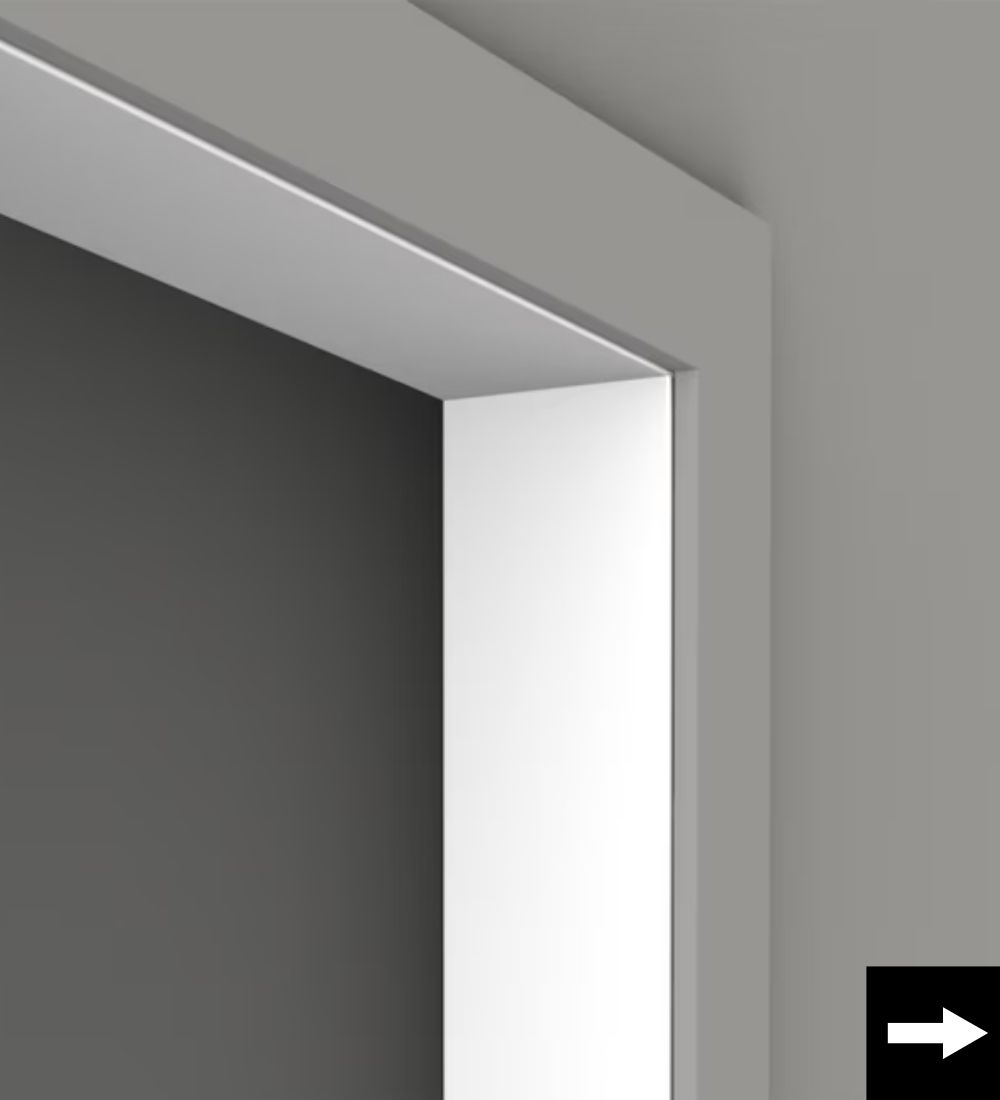

Installed where the wall meets the floor, base moulding protects walls from impact and creates a finished, cohesive look throughout the room.

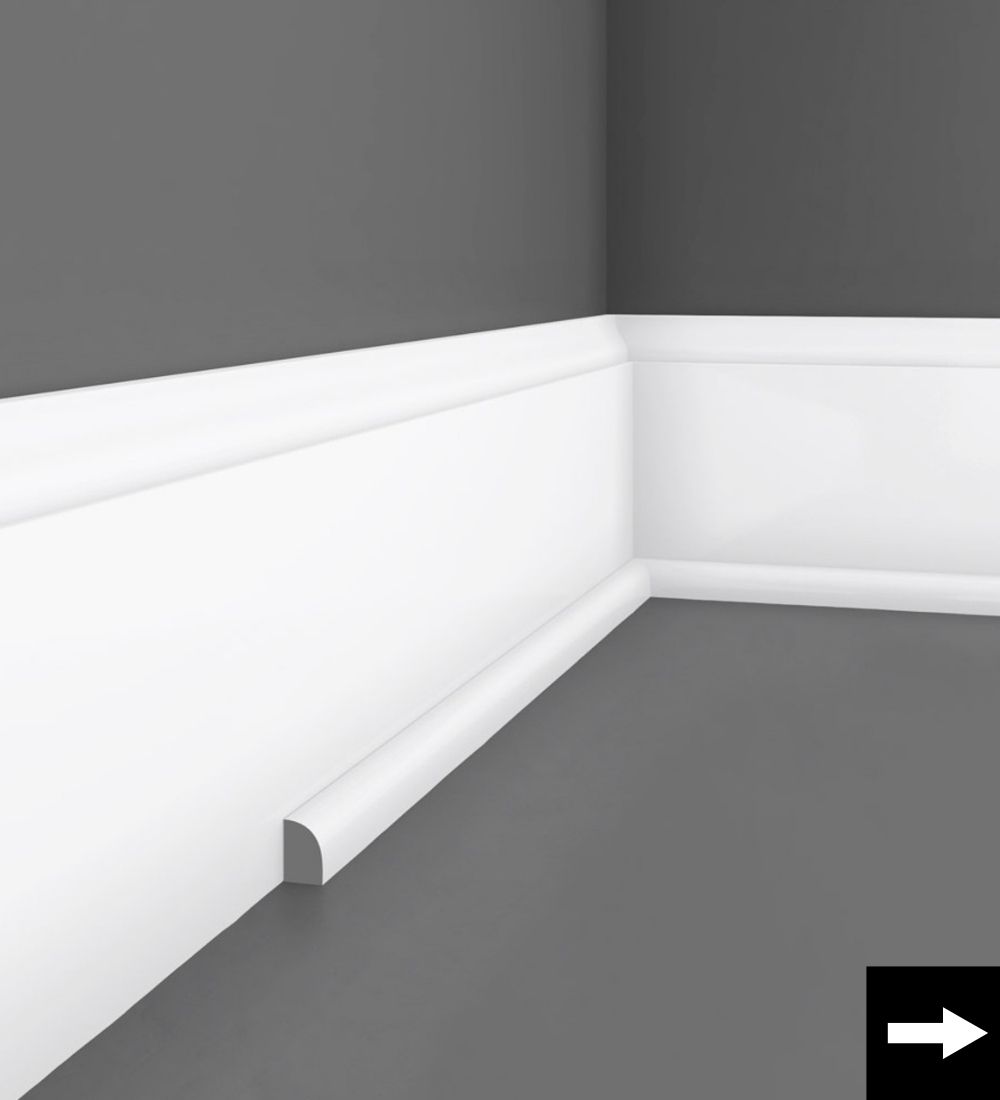

A decorative element installed where walls meet the ceiling, crown moulding adds depth, dimension, and elegance to any interior.

Door jambs form the vertical and horizontal framework that supports a door within its opening, ensuring a precise fit and smooth operation.

Door stops are fitted within the jamb to control the door’s closing position, preventing damage and creating a snug, finished seal.

A small, rounded trim piece installed at the bottom of base moulding to conceal gaps between the floor and wall, often used with hardwood or tile flooring.

Curved and smooth in profile, cove moulding is perfect for soft transitions between surfaces or as a decorative detail in cabinetry and ceilings.

Specially designed to meet fire-resistance requirements, fire-rated casing provides both safety and a clean, consistent appearance around rated door openings.

Panel moulding adds depth and texture to walls or ceilings, ideal for wainscoting, feature walls, or creating custom architectural detailing.

Used to hold glass securely within a door or frame, glass stop moulding ensures a safe, neat, and professional finish.

Additional trim profiles and specialty mouldings designed to meet unique design, installation, or restoration needs — available in a variety of materials and styles.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy