Base Moulding

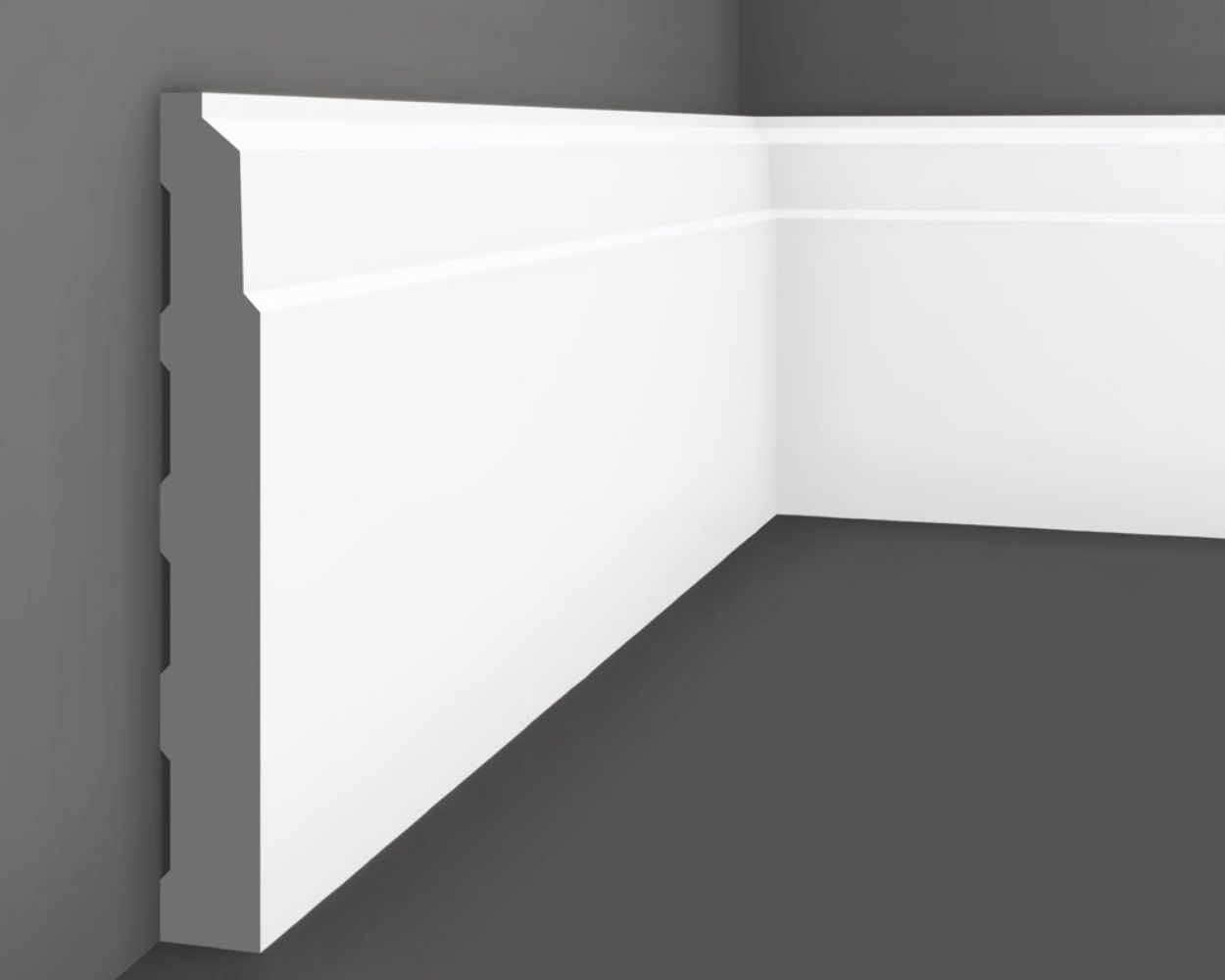

Are you looking for a way to bring everything together? Base molding is one of the easiest upgrades to finish a room, providing a clean transition between walls and floors while adding subtle architectural detail. At Woodwork Manufacturing & Supply, we offer a wide variety of molding profiles, from sleek and simple to ornate and traditional, to achieve the exact look you want for your project.

What is Base Moulding?

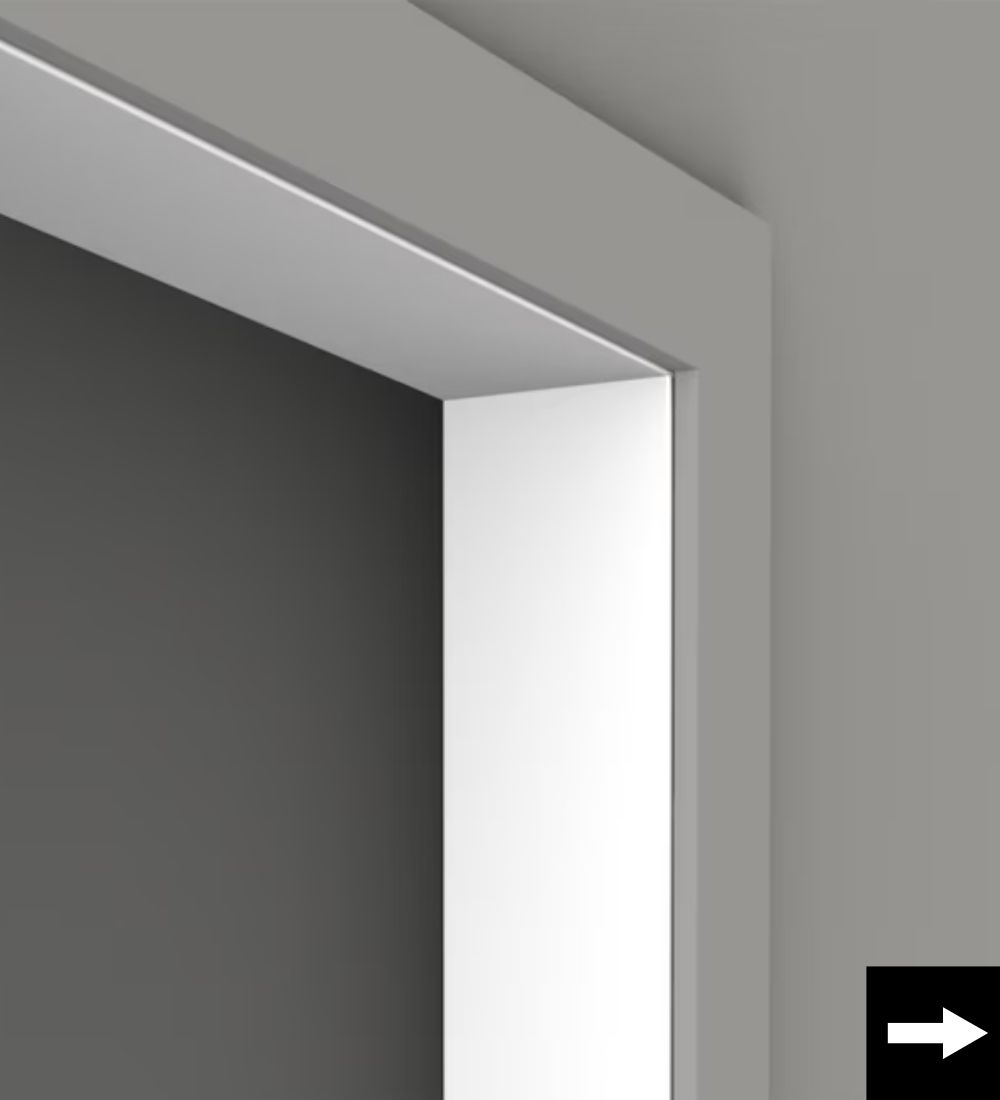

Also referred to as baseboard trim, this type of molding is the strip of material installed at the bottom of interior walls. Its primary purpose is to cover the joint where the wall meets the floor, hiding gaps and protecting walls from scuffs, kicks, and vacuum marks.

Beyond its practical function, it enhances your interior design, adding a polished, finished look to any space.

Base Moulding Profiles

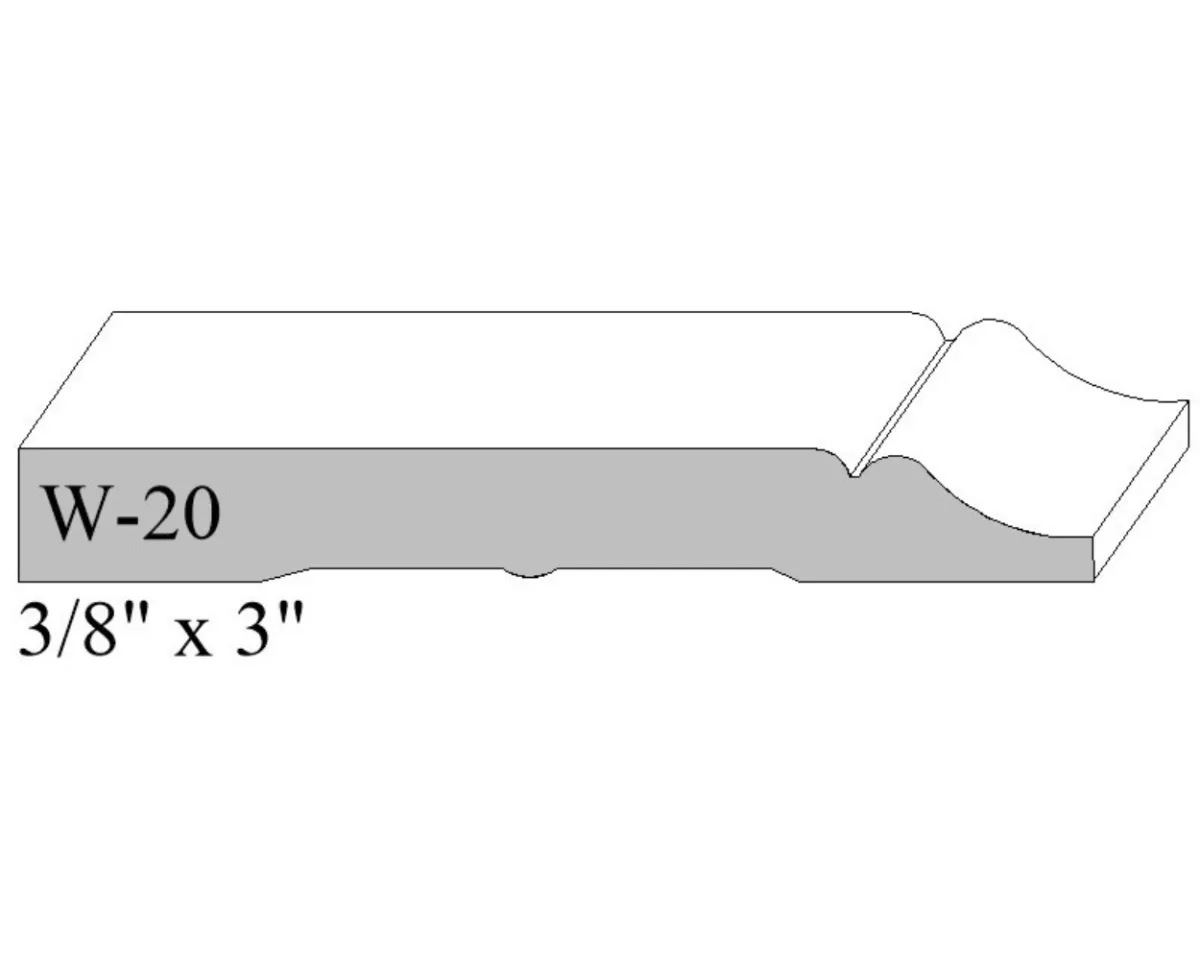

W-20

3/8" x 3"

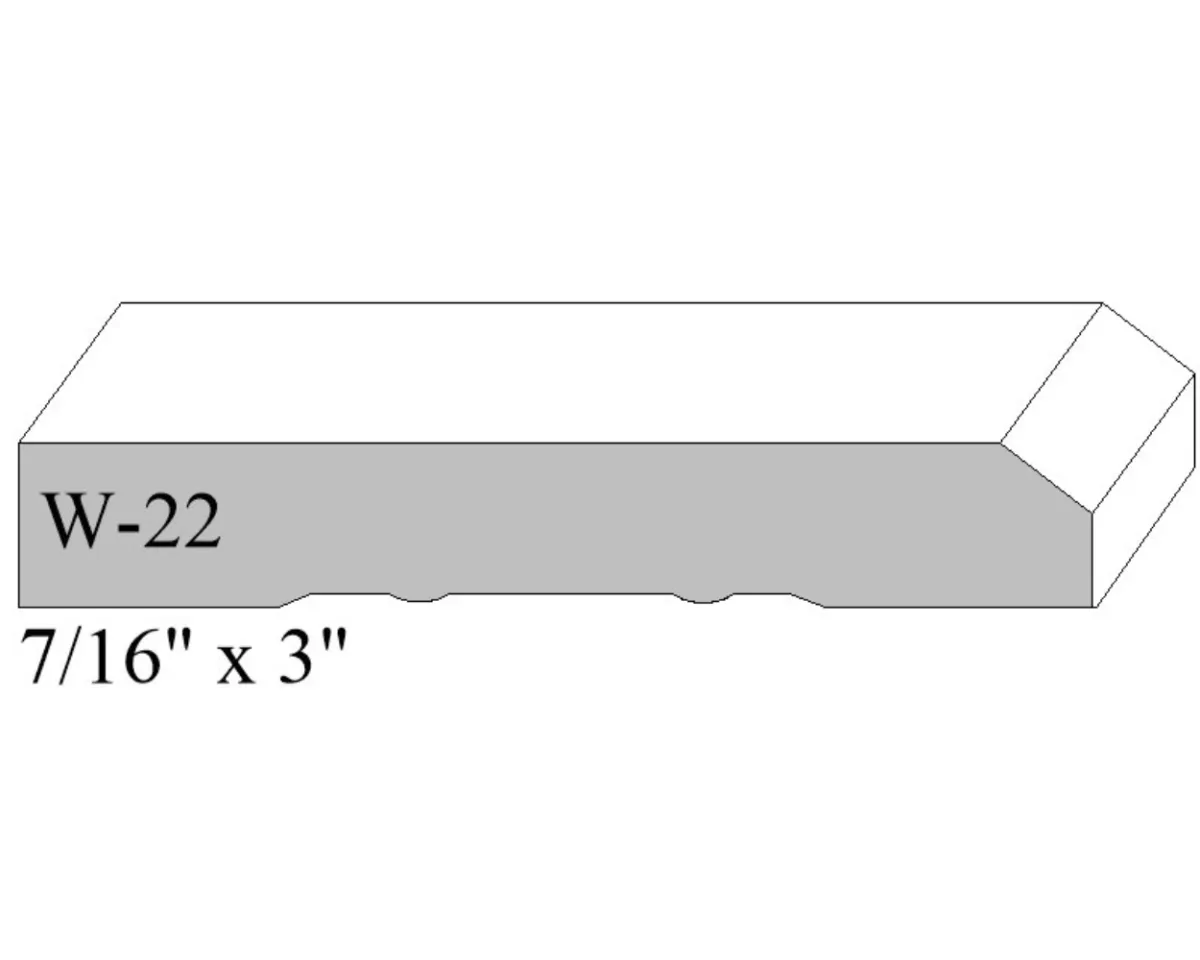

W-22

7/16" x 3"

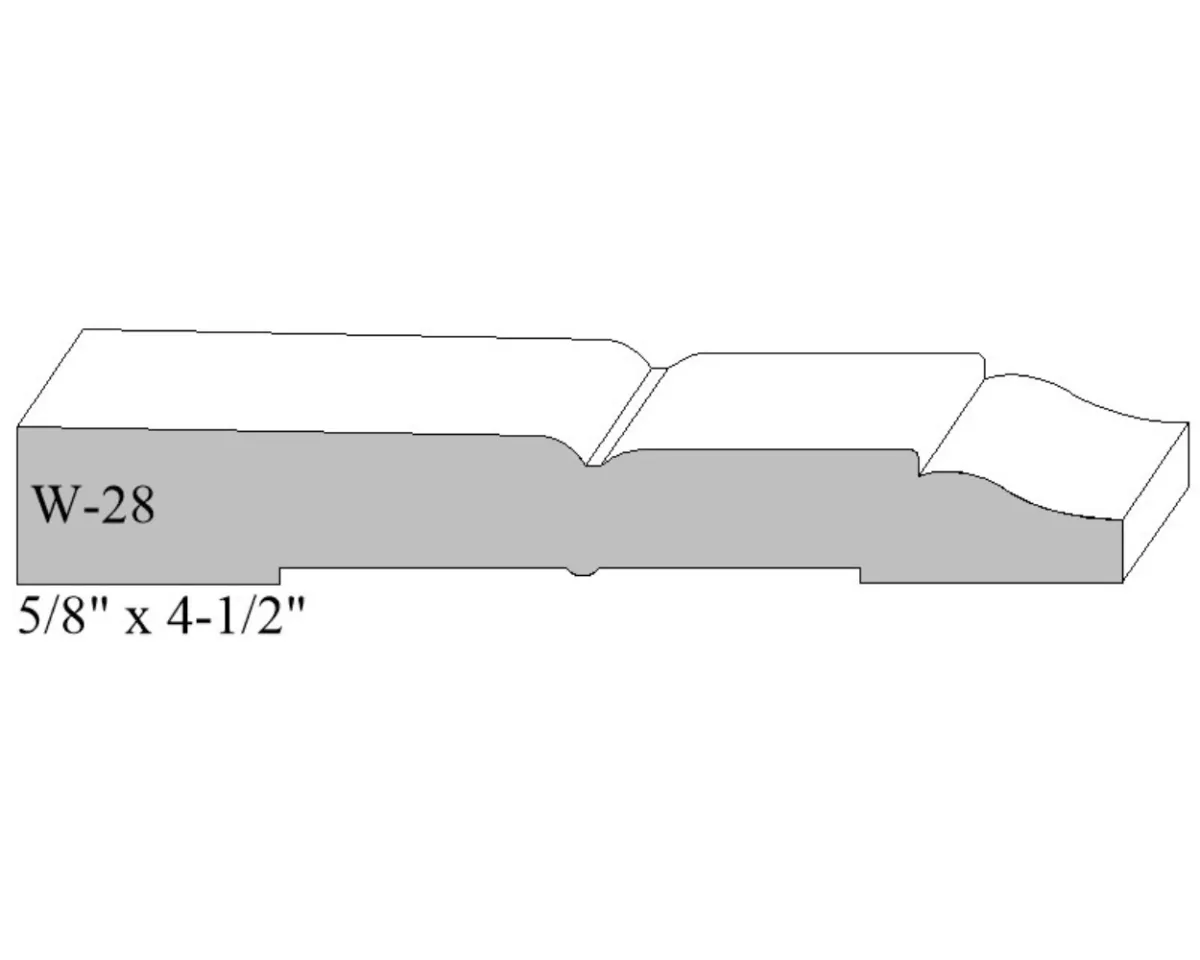

W-28

5/8" x 4-1/2"

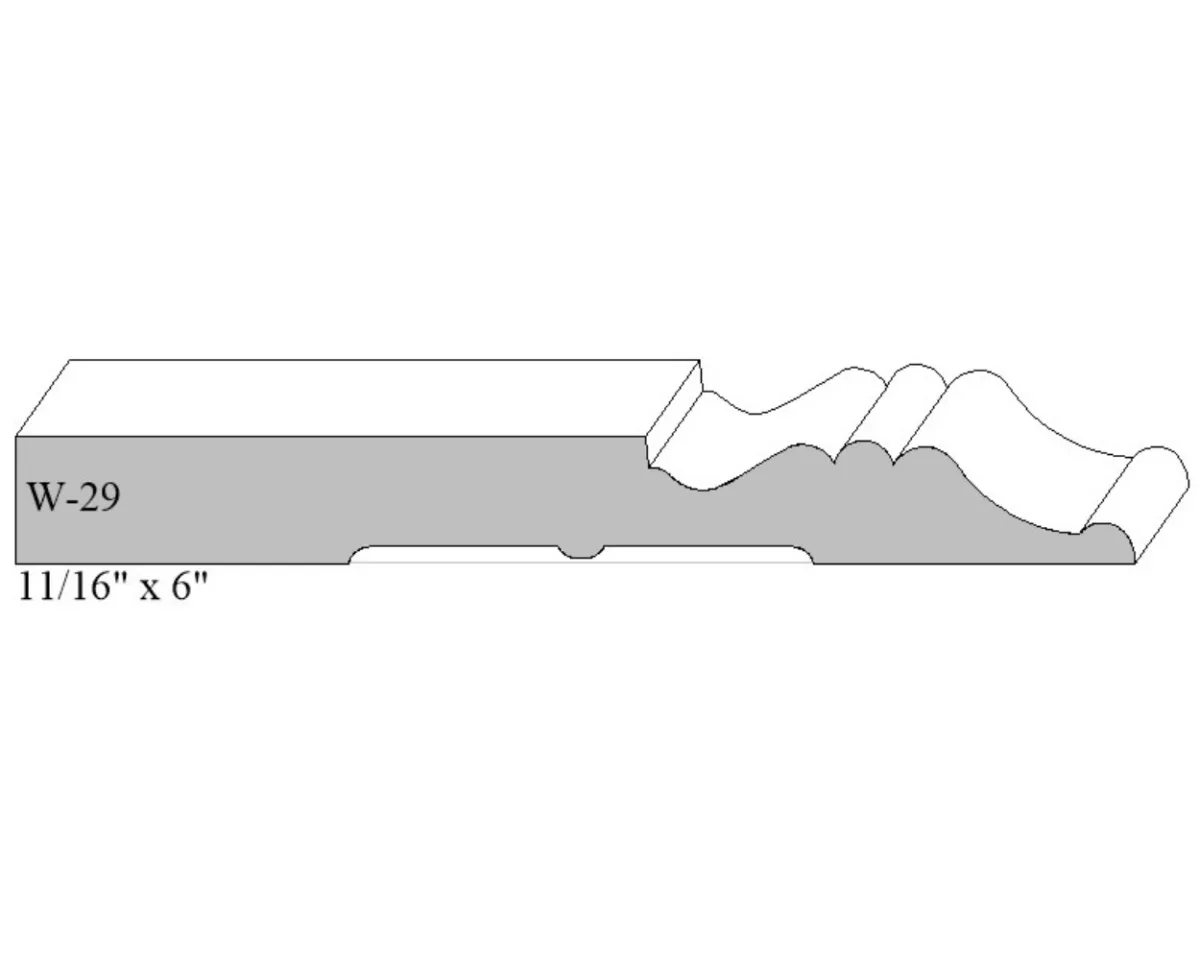

W-29

11/16" x 6"

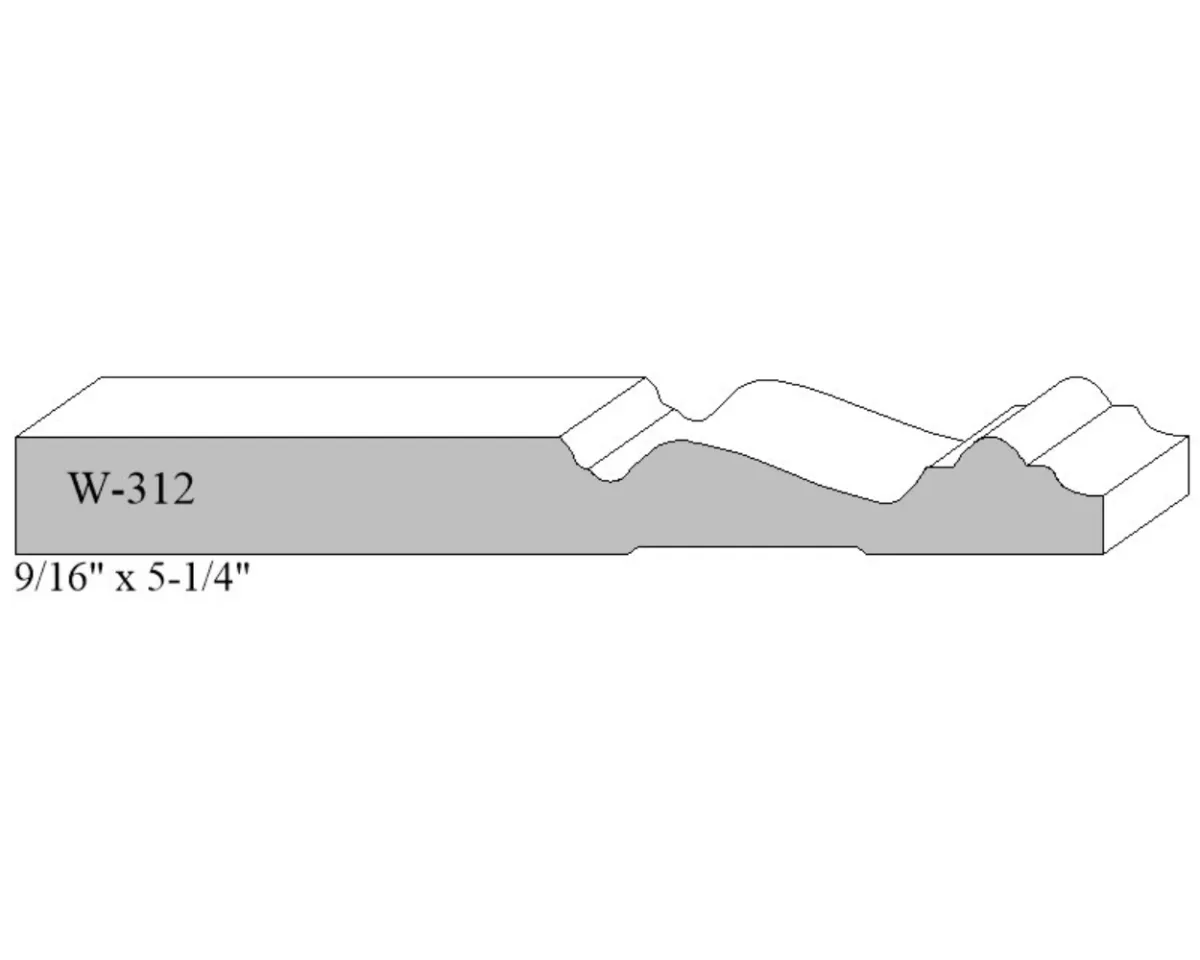

W-312

9/16" x 5-1/4"

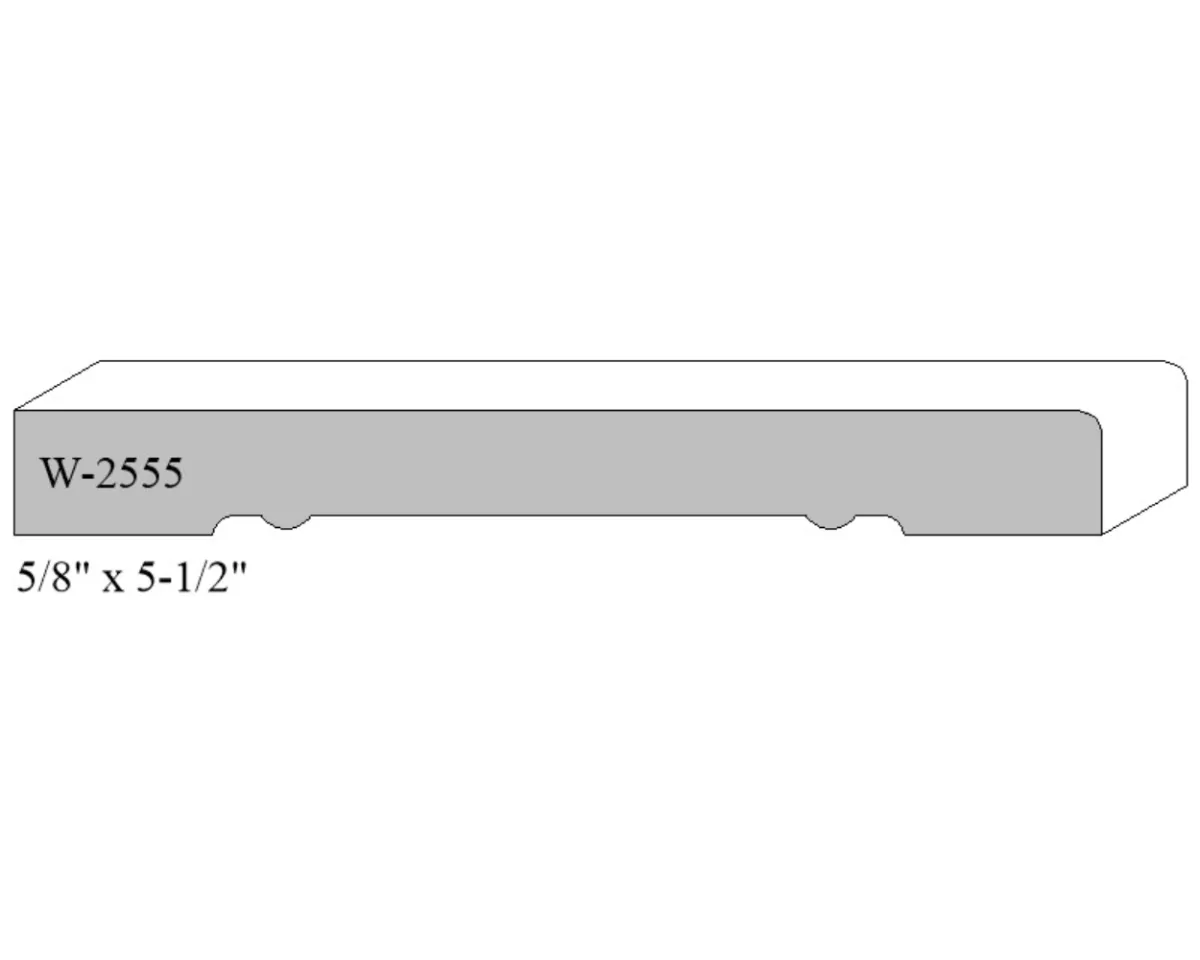

W-2555

5/8" x 5-1/2"

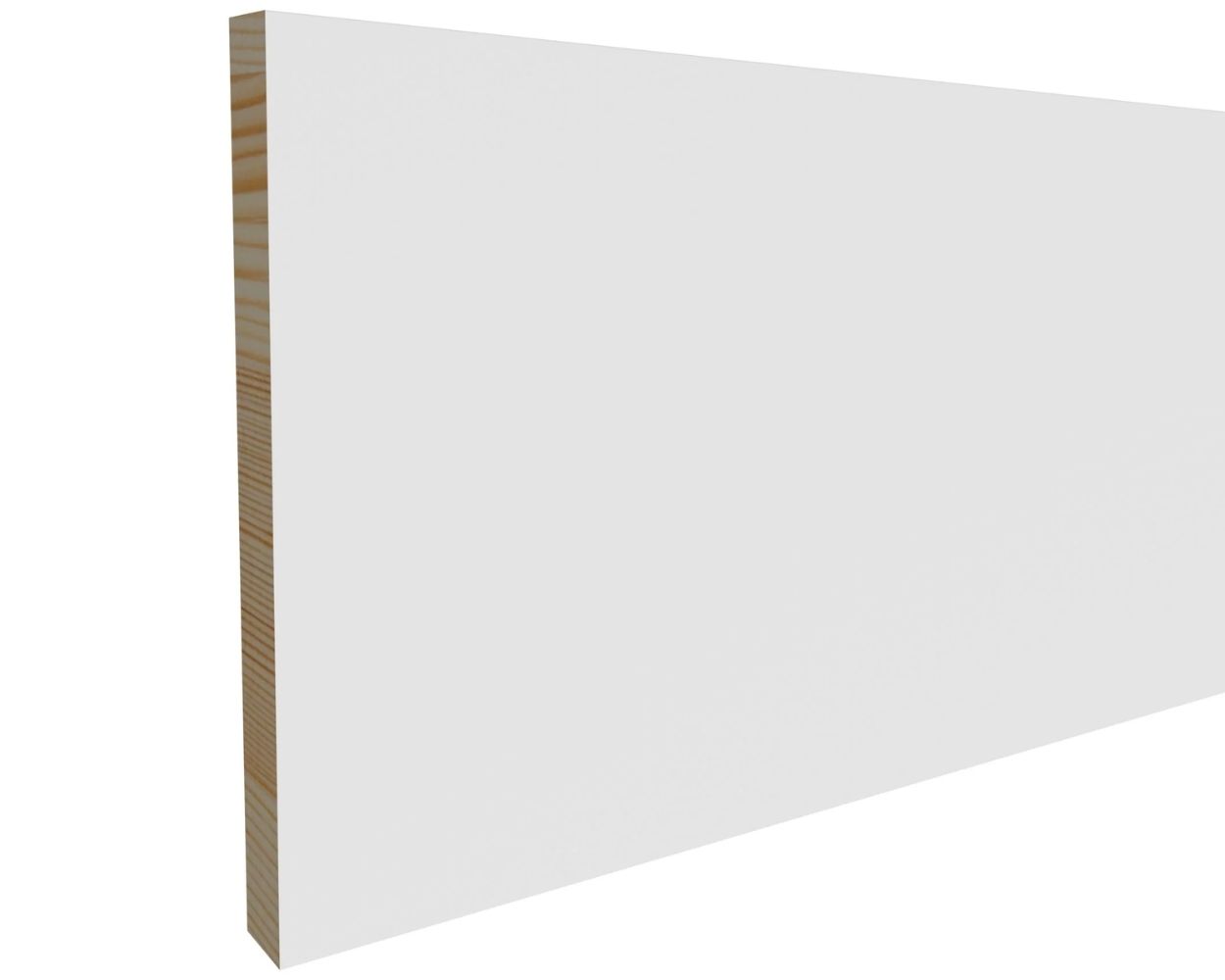

Base Moulding Wood Species

Oak

Maple

Poplar

Knotty Alder

Primed

Where to Use Base Molding

Living and Dining Rooms

Create a polished finishing touch to gathering spaces while protecting walls from furniture scuffs and daily wear.

Hallways and Entryways

Use durable profiles that withstand high traffic and frequent cleaning, keeping these busy areas looking sharp.

Bedrooms and Offices

Create a clean, finished edge that complements your flooring and adds subtle architectural interest.

Bathrooms and Basements

Choose moisture-resistant materials like composite or primed MDF to prevent swelling or damage in humid environments.

Open-Concept Spaces

Tie different rooms together with consistent base molding profiles for a seamless, cohesive design throughout your home or business.

Frequently Asked Questions

What materials are available for base molding?

Typically, this molding is made from wood, MDF (medium-density fiberboard), or composites. Wood offers timeless beauty and can be stained or painted. MDF is smooth and cost-effective, and composites resist moisture and warping, which is ideal for high-humidity areas.

How tall should base molding be?

The standard height ranges from 3 to 5 inches, but taller profiles - 6 inches or more - are typically used in larger rooms or homes with higher ceilings. The scale of your room and design style will determine the height you choose.

Can it be customized?

Yes! We offer a wide variety of profiles that can be further customized in size, material, and finish to suit your home’s unique qualities.

Does it require a lot of maintenance?

Not a ton. Typical routine dusting and occasional cleaning with a damp cloth will keep your molding looking fresh. Painted or stained finishes can be touched up as needed over time.

How does base molding coordinate with other trim?

It’s uniquely designed to complement casing, crown molding, and other millwork. Implementing matching or coordinated styles ensures a consistent design throughout your home.

Connect with a Moulding Expert

Have questions or interested in working with us? Contact us today to get started.

Types of Moulding Profiles

Choose Your Perfect Moulding Profiles

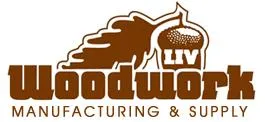

Used to frame doors and windows, casing moulding provides a clean transition between the wall surface and openings while adding architectural definition.

Installed where the wall meets the floor, base moulding protects walls from impact and creates a finished, cohesive look throughout the room.

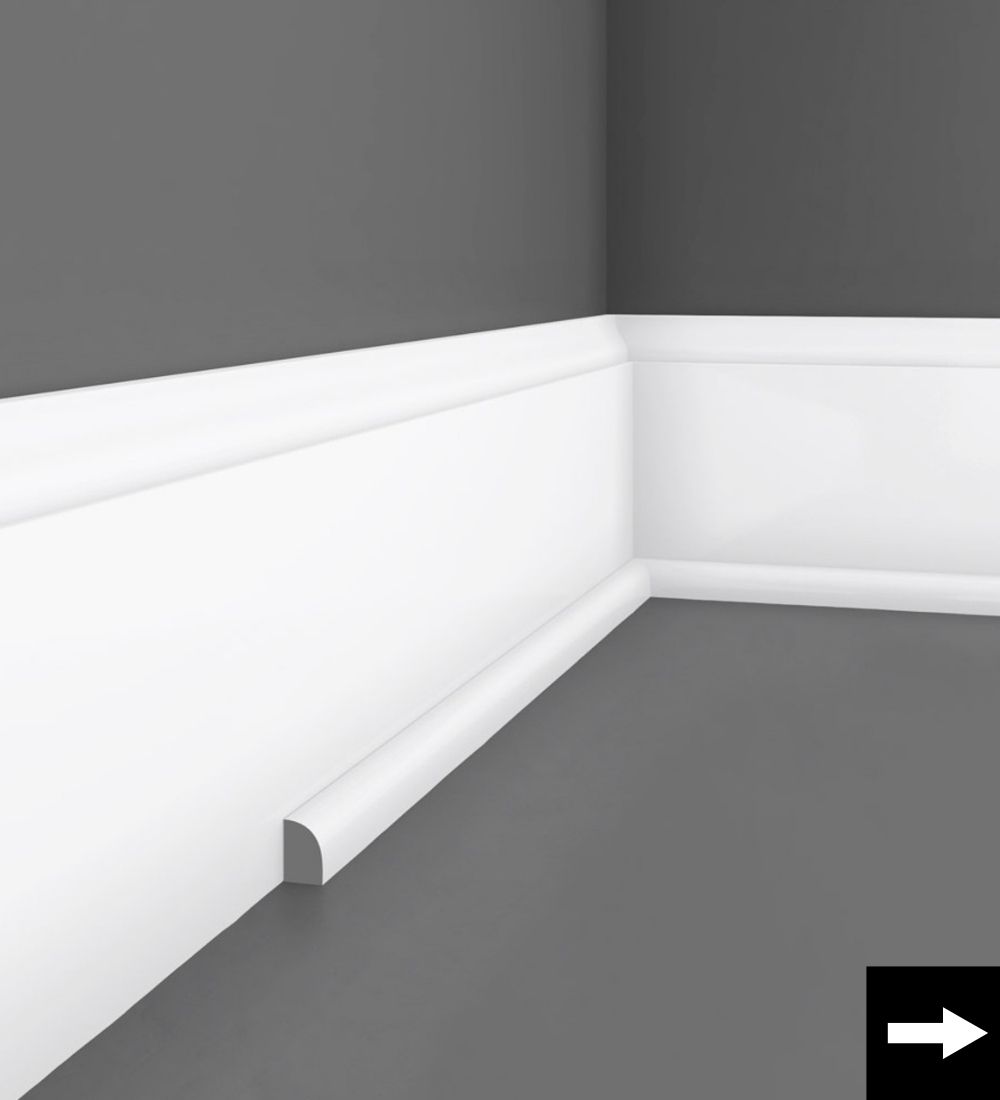

A decorative element installed where walls meet the ceiling, crown moulding adds depth, dimension, and elegance to any interior.

Door jambs form the vertical and horizontal framework that supports a door within its opening, ensuring a precise fit and smooth operation.

Door stops are fitted within the jamb to control the door’s closing position, preventing damage and creating a snug, finished seal.

A small, rounded trim piece installed at the bottom of base moulding to conceal gaps between the floor and wall, often used with hardwood or tile flooring.

Curved and smooth in profile, cove moulding is perfect for soft transitions between surfaces or as a decorative detail in cabinetry and ceilings.

Specially designed to meet fire-resistance requirements, fire-rated casing provides both safety and a clean, consistent appearance around rated door openings.

Panel moulding adds depth and texture to walls or ceilings, ideal for wainscoting, feature walls, or creating custom architectural detailing.

Used to hold glass securely within a door or frame, glass stop moulding ensures a safe, neat, and professional finish.

Additional trim profiles and specialty mouldings designed to meet unique design, installation, or restoration needs — available in a variety of materials and styles.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy