Crown Moulding

Crown moulding is a classic statement of sophistication in a home or building project! It adds an instant touch of elegance, framing the junction where your walls meet the ceiling with timeless grace. At Woodwork Manufacturing & Supply, we offer a broad selection of moulding profiles, ranging from simple modern lines to richly detailed traditional designs - perfect for giving any room that refined finishing touch.

What is Crown Moulding?

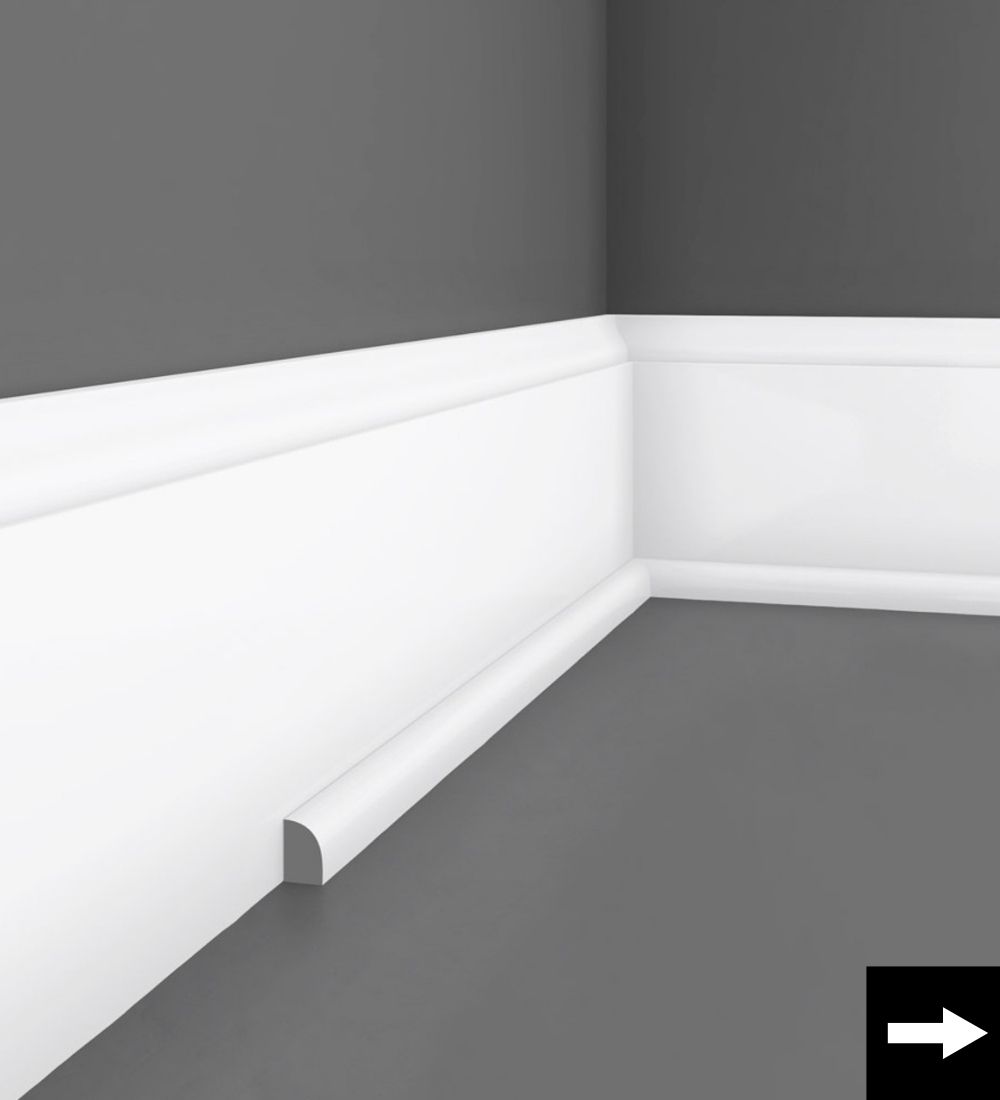

Crown moulding is a type of decorative trim installed where the wall meets the ceiling, creating a smooth, finished transition between the two surfaces. More than just a design accent, it adds a sense of height and elegance to a room, drawing the eye upward and giving the space a more refined look.

Depending on your style, this type of moulding can be simple and understated with clean lines, or it can be built up in layers with intricate patterns for added depth and character. It’s available in a variety of materials and finishes, making it versatile enough to complement modern, traditional, or transitional interiors.

Crown Moulding Profiles

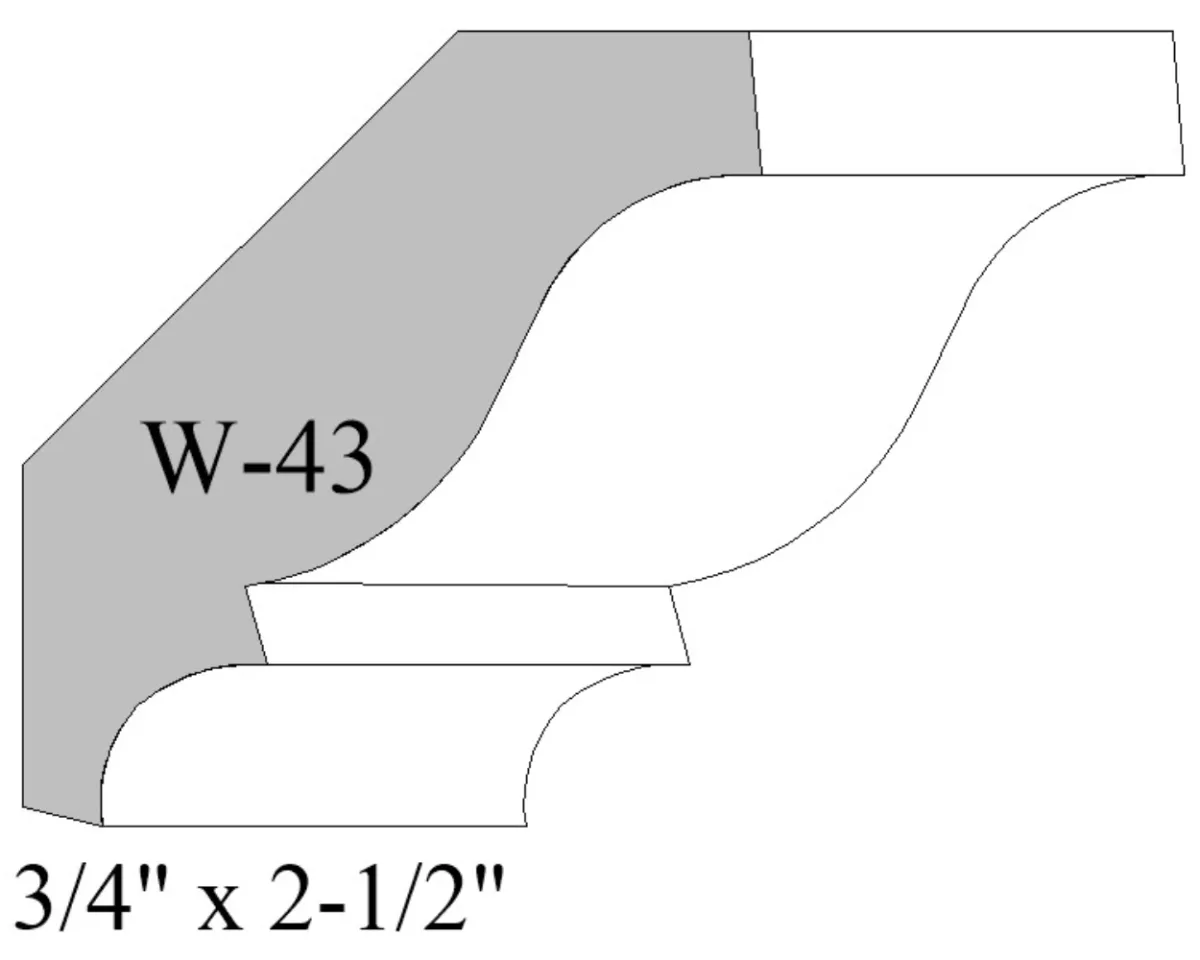

W-43

3/4" x 2-1/2"

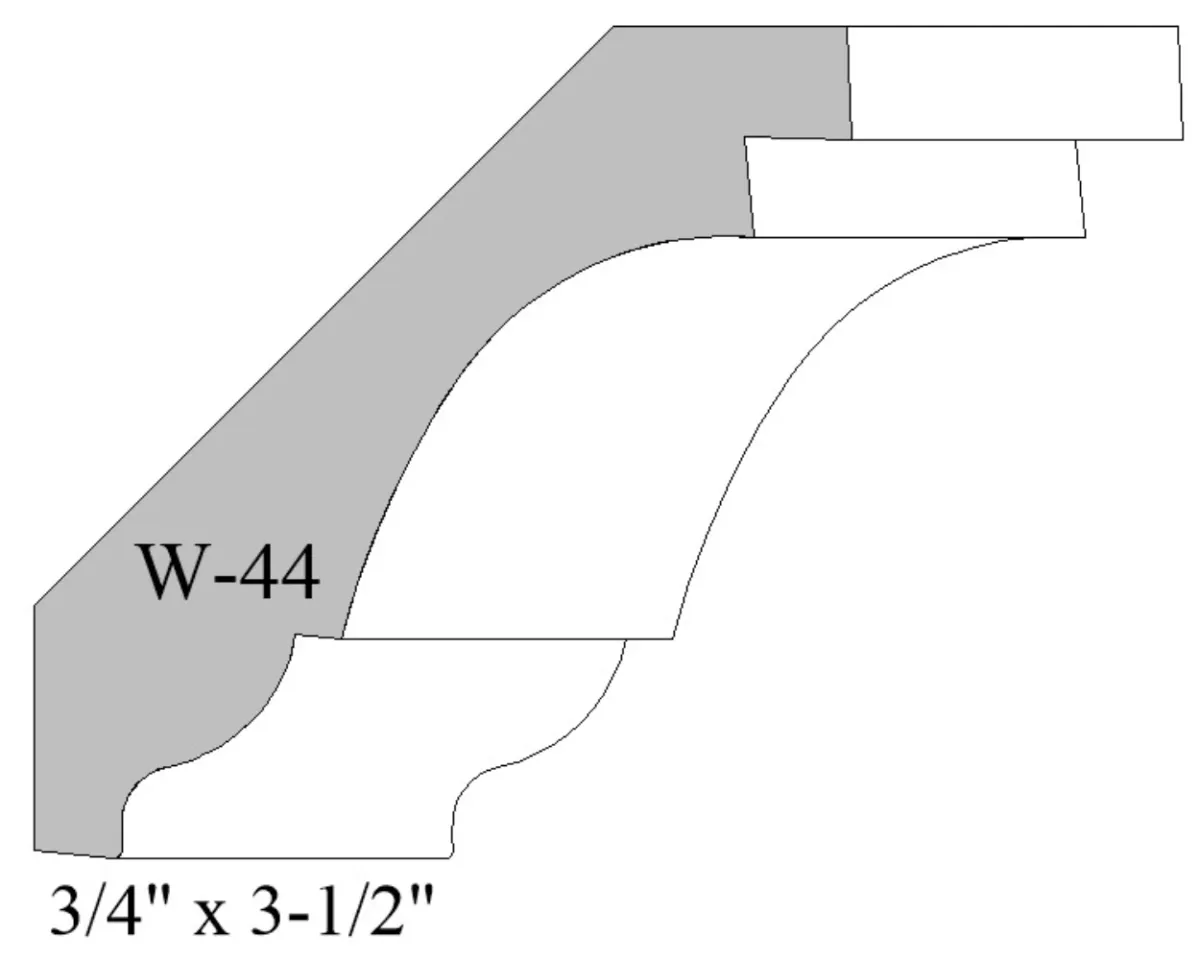

W-44

3/4" x 3-1/2"

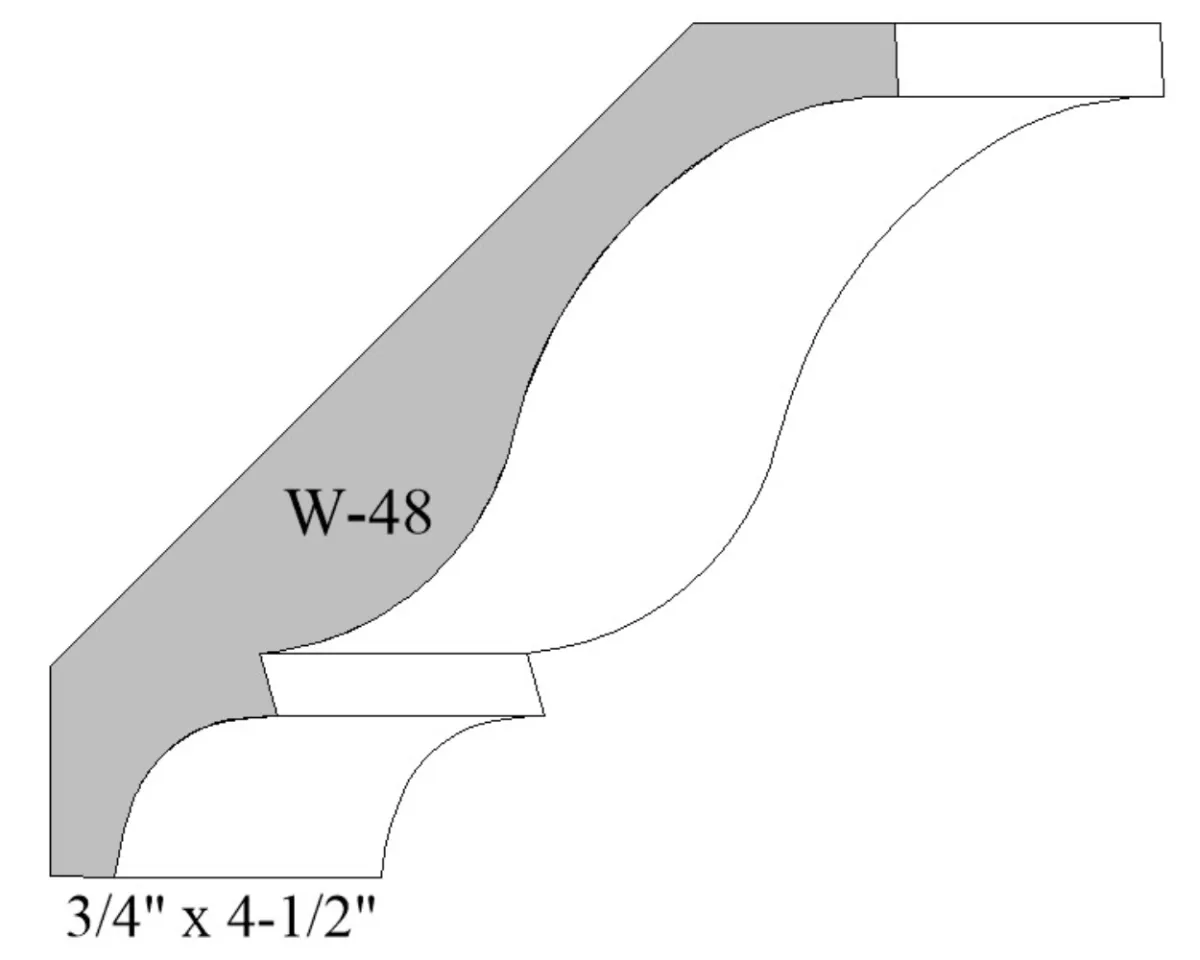

W-48

3/4" x 4-1/2"

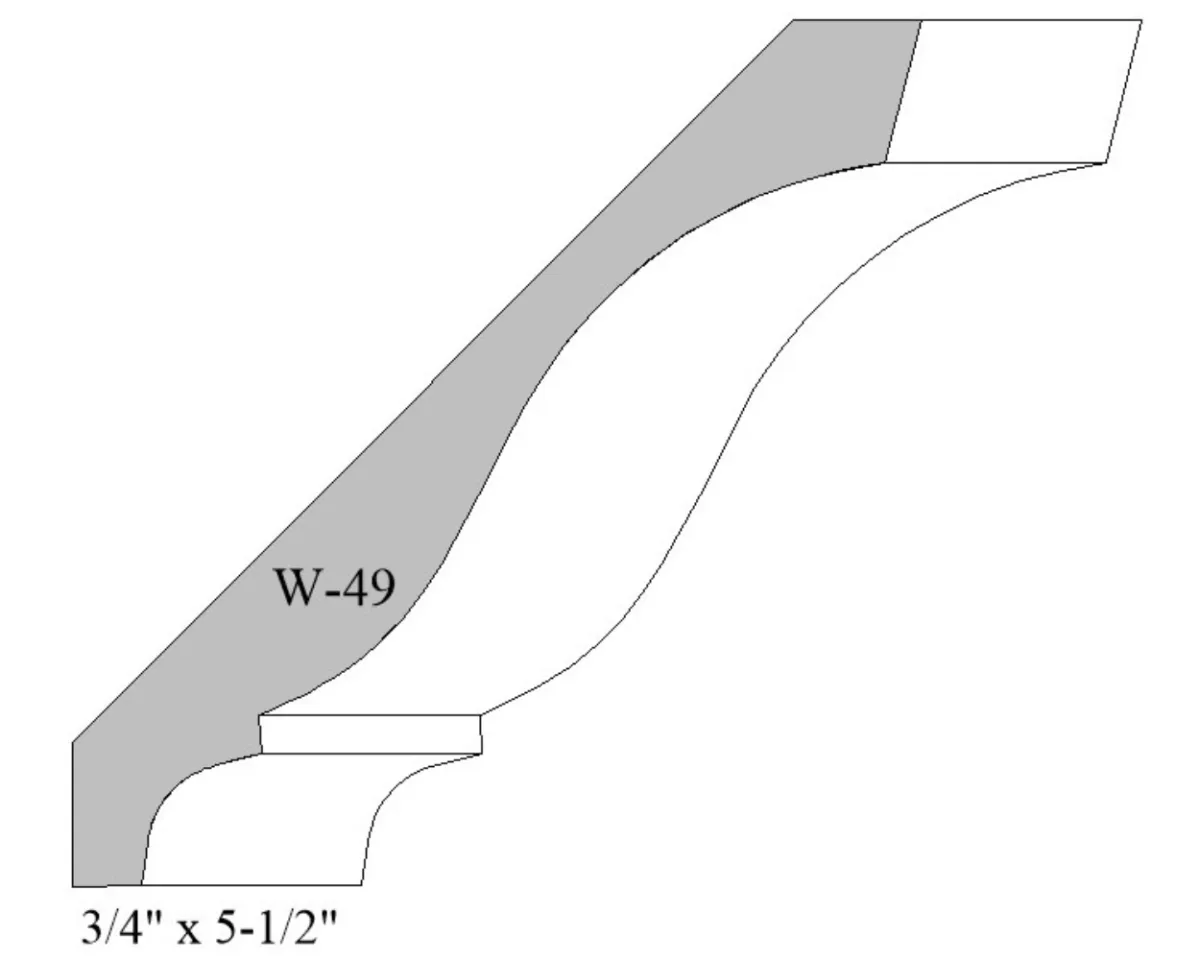

W-49

3/4" x 5-1/2"

Crown Moulding Wood Species

Oak

Maple

Poplar

Knotty Alder

Primed

Where to Use Crown Moulding

Living Rooms and Dining Areas

Frame your ceilings with crown molding to create a polished, high-end look that instantly elevates the space and ties your design together.

Entryways and Hallways

Make a strong first impression by adding molding that enhances height and definition in transitional areas.

Bedrooms and Offices

Use simple or decorative profiles to bring warmth and sophistication to private or work spaces without overwhelming the room.

Kitchens and Bathrooms

Install moisture-resistant materials or painted MDF crown molding to achieve a refined finish even in high-humidity areas.

Whole-Home Trim Designs

Coordinate crown molding with your baseboards and casing for a consistent, custom-finished style that flows naturally from room to room.

Frequently Asked Questions

What materials are crown mouldings available in?

The most common materials include hardwood (like pine or oak) for a timeless natural look, primed MDF for easy painting, and moisture-resistant composites for use in damp areas like bathrooms or basements.

How tall should crown moulding be?

The standard sizes range from 3 to 6 inches in height, but larger rooms or ceilings over eight feet often benefit from taller profiles, sometimes 7–9 inches, to match the room’s scale and proportions.

Can this moulding be customized?

Absolutely! We provide custom lengths, profiles, and materials to suit your project. You can also choose the paint or stain in your choice of finishes to match your home’s design palette.

Is it Difficult to install?

This type of moulding installation requires precise angle cuts, especially on inside/outside corners. Many of our customers choose professionals for a pristine fit, but premade corner block systems make DIY installation much more manageable.

Does crown moulding serve any functional purpose?

Though it primarily is for decor, it also helps conceal small gaps or uneven seams where walls meet the ceiling, providing a finished look and adding a touch of architectural polish.

Connect with a Moulding Expert

Have questions or interested in working with us? Contact us today to get started.

Types of Moulding Profiles

Choose Your Perfect Moulding Profiles

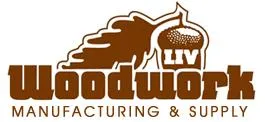

Used to frame doors and windows, casing moulding provides a clean transition between the wall surface and openings while adding architectural definition.

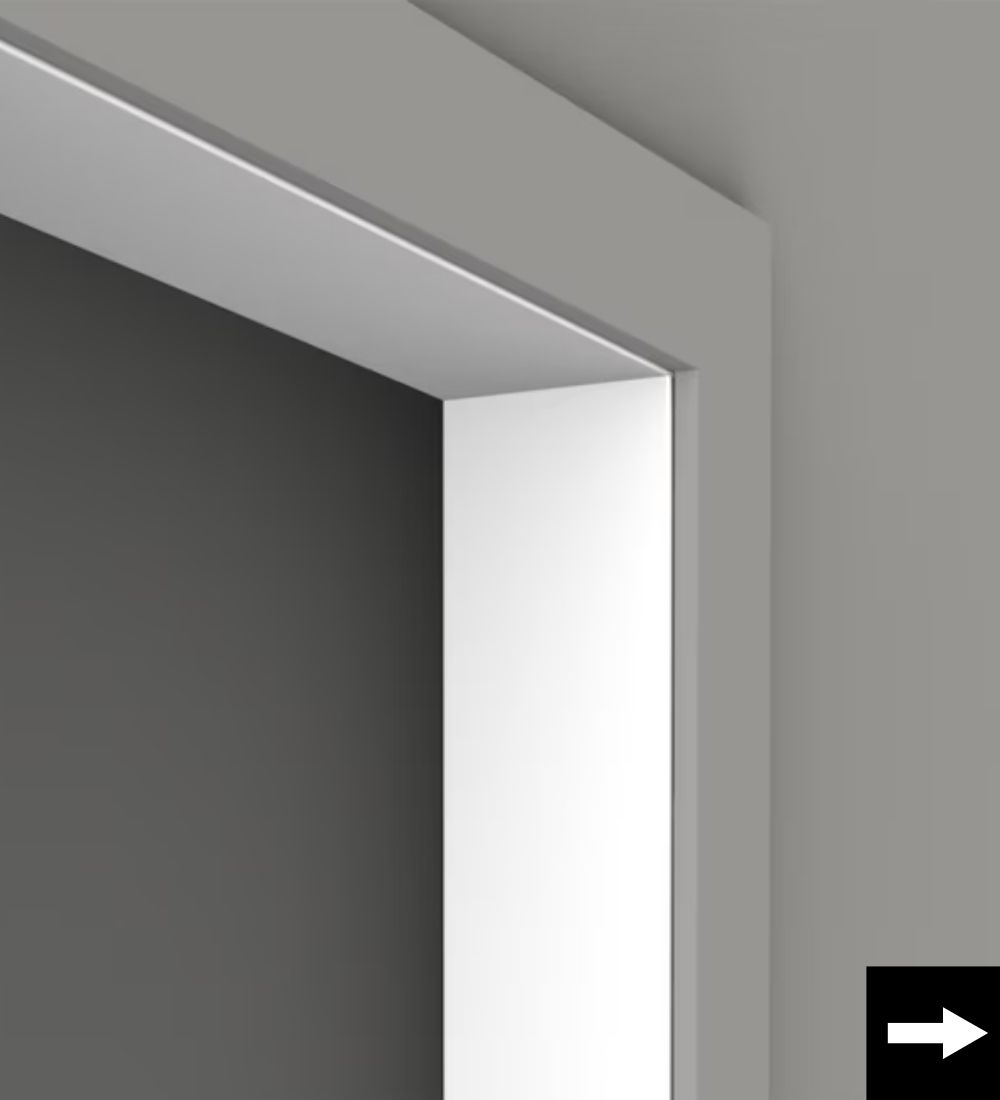

Installed where the wall meets the floor, base moulding protects walls from impact and creates a finished, cohesive look throughout the room.

A decorative element installed where walls meet the ceiling, crown moulding adds depth, dimension, and elegance to any interior.

Door jambs form the vertical and horizontal framework that supports a door within its opening, ensuring a precise fit and smooth operation.

Door stops are fitted within the jamb to control the door’s closing position, preventing damage and creating a snug, finished seal.

A small, rounded trim piece installed at the bottom of base moulding to conceal gaps between the floor and wall, often used with hardwood or tile flooring.

Curved and smooth in profile, cove moulding is perfect for soft transitions between surfaces or as a decorative detail in cabinetry and ceilings.

Specially designed to meet fire-resistance requirements, fire-rated casing provides both safety and a clean, consistent appearance around rated door openings.

Panel moulding adds depth and texture to walls or ceilings, ideal for wainscoting, feature walls, or creating custom architectural detailing.

Used to hold glass securely within a door or frame, glass stop moulding ensures a safe, neat, and professional finish.

Additional trim profiles and specialty mouldings designed to meet unique design, installation, or restoration needs — available in a variety of materials and styles.

© 2026 Woodwork Manufacturing. All Rights Reserved.

Terms & Conditions | Privacy Policy